Pipeline type dust concentration detection bag dust leak detector plug-in type

Category: Products On-line dust detector Pipeline dust concentration detector

Key words: Products

Model: SK/MIC-600-PM

Measurement object: Dust

Category: Products On-line dust detector Pipeline dust concentration detector

Key words: Products

Model: SK/MIC-600-PM

Measurement object: Dust

Previous: No more data

Next: No more data

Product Description

Product parameters of pipeline dust concentration detector

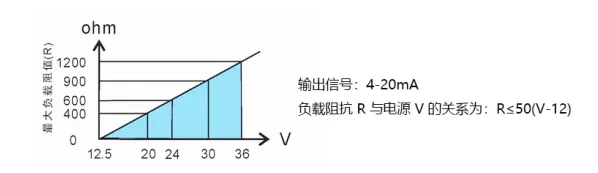

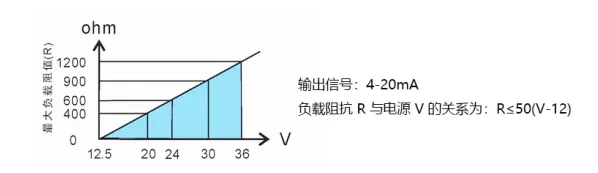

| Output signal |

① 4-20mA signal: standard 12-bit precision 4-20mA output chip, transmission distance 1Km ② RS485 signal: standard MODBUS RTU protocol, transmission distance 1Km ③ voltage signal: 0.4-2V,0-5V,0-10V output, optional (voltage output and current output two choose one) ④ Switching signal: standard 1 set of passive contact relay, capacity 220VAC3AV/24VDC3A |

GPRS, 4G, WIFI, LORA, ZigBee and other wireless signals | |

| Measuring gas | Dust | Detection principle | Electrostatic principle |

| Range selection | 100mg/m3 (more range inquiry customer service) | Resolution | 0.1mg/m3 |

| Sampling accuracy | ±5%F.S | Pipeline flow rate | 1m/s~30m/s |

| Working temperature | -20~50 ℃ | Working humidity | 0-95%RH |

| Storage temperature | -20~50 ℃ | Pipeline pressure | -0.1 - 1MPa |

| Working current | ≤50mA | zero drift | (Time) is less than 1% of the range per year, and (temperature) is less than 1% of the range within the specified temperature range. |

| Operating voltage | DC5V±1%/DC24±1% | Baud rate | 9600 |

| Installation method | Plug-in dust detector | Warranty period | 1 year |

| Shell material | Aluminum alloy | Service life | 1 to 3 years |

| Protection level | IP66 waterproof splash and short time rain | Explosion-proof grade | E x d I IC T 6 |

| Receiving equipment | User computer, control alarm, PLC, DCS, DDC, etc. | ||

| Alarm mode | On-site sound and light alarm, external alarm, remote controller alarm, computer data acquisition software alarm, etc. | ||

| Alarm Settings | Standard configuration of two-level alarm, optional three-level alarm; alarm mode can be set: regular high and low alarm, interval control alarm | ||

| Connection cable |

① Select three-core shielded cable for 4 ~ 20mA and four-core cable for RS485. When the distance exceeds 1000 m (with a detector), the single wire diameter shall be ≥ 1.5mm, and the shielding layer shall be connected to the ground. ② wireless transmission: can be built-in LORA, Zigbeg module, short-range wireless transmission; external GPRS/4G module, remote data transmission to the cloud platform, can be viewed on the computer side and mobile phone side of the history, not limited by distance (optional) |

||

| Optional accessories |

Computer monitoring accessories: free upper computer software, USB to RS485 conversion cable, RS485 to network port converter if network transmission is required. Mounting bracket |

||

Working principle of pipeline dust concentration detector

The dust concentration detector measures the amount of electrostatic charge induced by dust particles passing through a fixed probe. The dust particles induce electrostatic charge with the probe, and the signal is amplified by the probe and transmitted into the monitoring and control system. The magnitude of the electrostatic charge is proportional to the flux of the dust particles. The high-tech electronic circuit of the system converts this part of the charge into a control signal output to start the dust emission alarm, and is used to continuously record the total amount or concentration of dust particles.

The device provides the latest AC coupling technology in the world. This is the most accurate and stable monitoring technology in modern times, especially suitable for continuous emission recording and data accumulation. The working principle of this monitoring system is to use the charge induction generated by dust particles flowing around the probe to confirm the online emission (mg/sec) or emission concentration (mg/m3) of dust particles. In the case of relatively stable combustion conditions (that is, at the same discharge point, the flow rate, temperature, pressure, humidity and soot particle properties have not changed much, less than ± 90% of the change), the system can also be used for online monitoring of emission concentration (unit = mg/M3) after direct calibration.

Application Scenarios

Petroleum and petrochemical, chemical plants, smelters, steel plants, coal plants, thermal power plants, pharmaceutical research, pharmaceutical production workshops, tobacco companies, environmental monitoring, school research, building construction, fire alarm, sewage treatment, industrial gas process control, boiler room, Garbage treatment plant, tunnel construction, oil pipeline, gas filling station, underground gas pipeline maintenance, indoor air quality inspection, safety protection in hazardous places, aerospace, military equipment monitoring, etc.

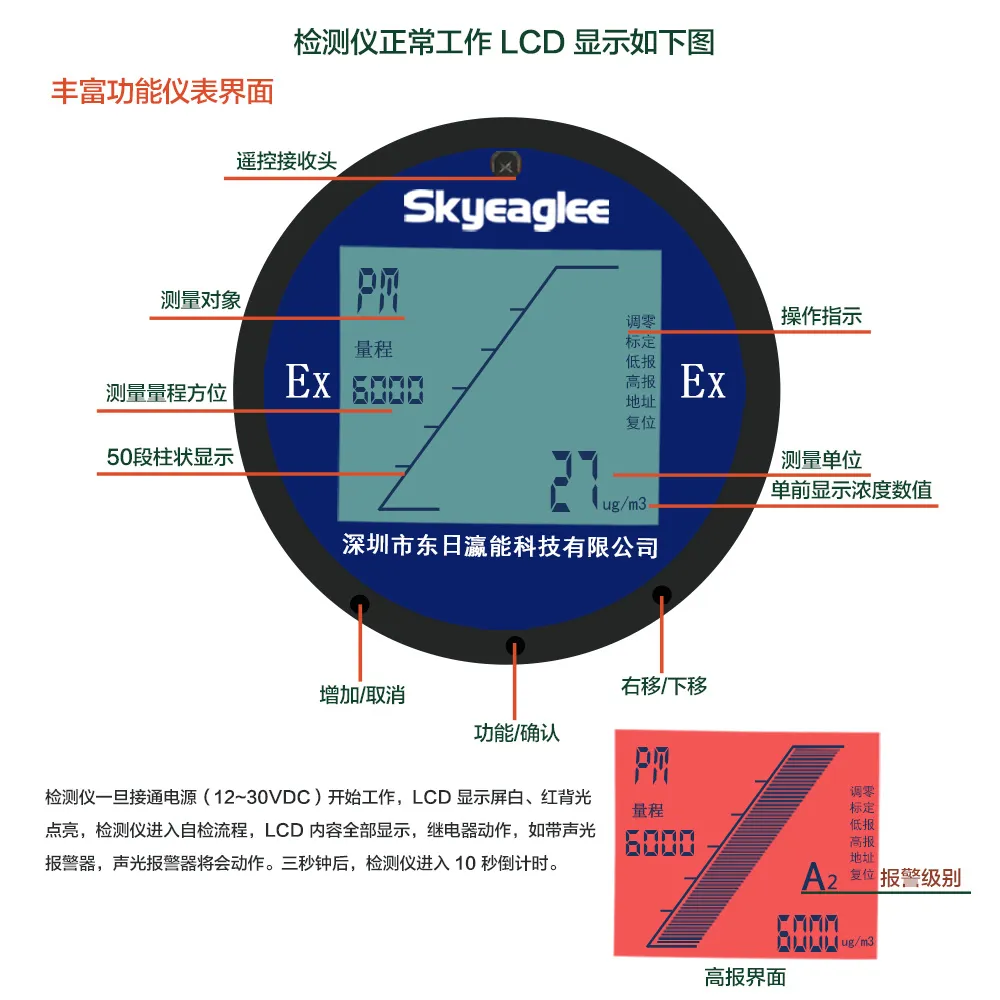

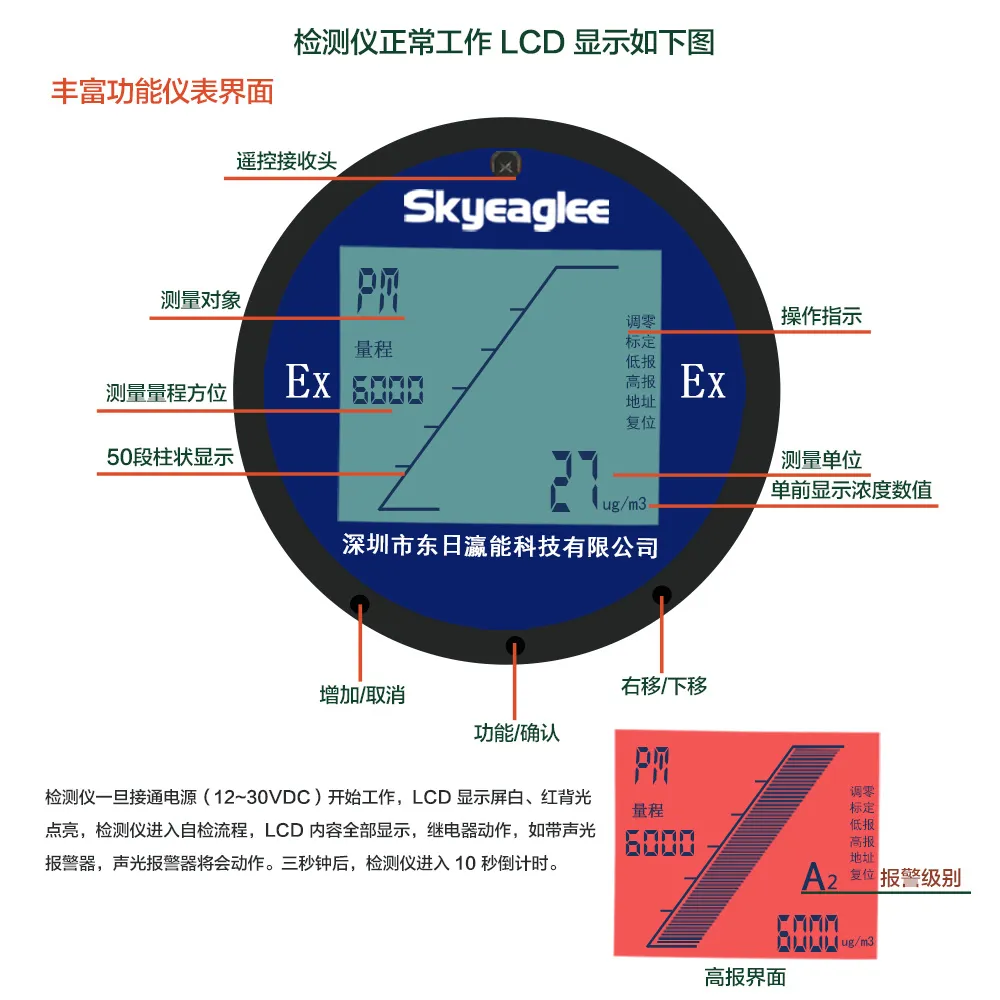

On-line dust concentration detector interface display introduction

The instrument has a total of 3 buttons, namely "add/cancel", "function/confirm", "move right/down" (hereinafter referred to as "add" ("cancel"), "function" ("confirm"), "move right" ("move left")). The three key positions are as follows. Press the "Function" button.

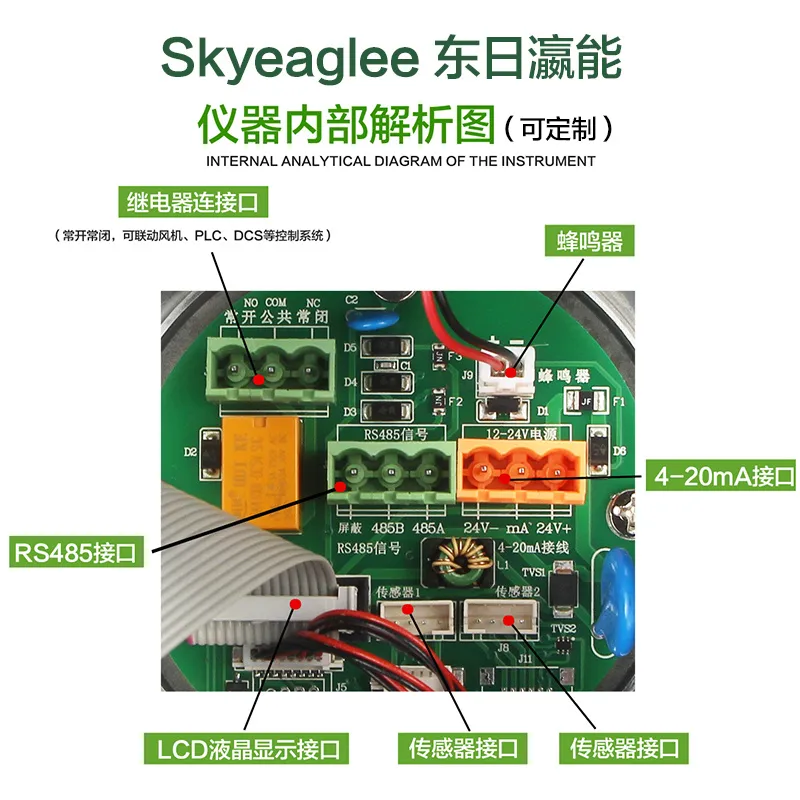

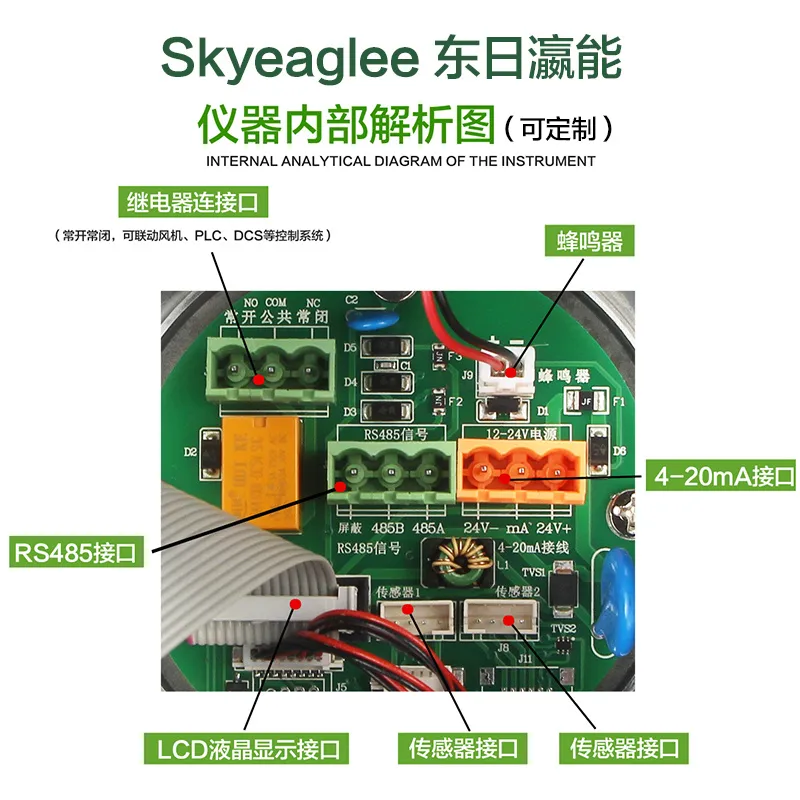

Internal diagram of online dust concentration detector

Installation and Precautions

The sensor is best installed in the vertical pipe, from the valve, elbow more than 5 times the diameter of the pipe, to be in the horizontal pipe sampling, shall not be installed at the bottom. For the gas dust removal system with multiple boxes running in parallel, a hole shall be opened on the pipeline before entering the net gas main pipe at the outlet of the tested dust removal box (the opening size is φ32mm), and the base interface end of the fixed sensor shall be vertically welded to the top of the horizontal pipeline with a longer straight pipe section.

② The length of the sensor probe, according to the user's need to measure the diameter of the pipe, is selected and supplied by the instrument manufacturer. The base shall be that the top of the insulating sleeve of the sensor probe is level with the inner wall of the pipeline or protrudes out of the inner wall of the pipeline. The base is supplied by the instrument manufacturer.

③ Add copper pad between the sensor and the socket, connect with screw thread and tighten to prevent the leakage of toxic gas in the pipe.

④ The sensor junction box is rainproof. The signal cable is directly connected to the connection terminal in the box through the threading hole on the junction box, and then the sealing rubber ring is compressed. The external cable should be fixed nearby to prevent it from swinging back and forth in wind and rain. Mechanical damage to the transmission wire.

Attention during installation

1. The base and length of the sensor shall be provided by the manufacturer. The opening size of the base in the pipeline shall be φ 32±2mm.

2, the transmission wire please choose 0.75mm2 -- 1.5mm2 ordinary twisted pair (in a particularly strong interference environment, please use a shielded double-core cable, and the shielding layer is well grounded).

Product parameters of pipeline dust concentration detector

| Output signal |

① 4-20mA signal: standard 12-bit precision 4-20mA output chip, transmission distance 1Km ② RS485 signal: standard MODBUS RTU protocol, transmission distance 1Km ③ voltage signal: 0.4-2V,0-5V,0-10V output, optional (voltage output and current output two choose one) ④ Switching signal: standard 1 set of passive contact relay, capacity 220VAC3AV/24VDC3A |

GPRS, 4G, WIFI, LORA, ZigBee and other wireless signals | |

| Measuring gas | Dust | Detection principle | Electrostatic principle |

| Range selection | 100mg/m3 (more range inquiry customer service) | Resolution | 0.1mg/m3 |

| Sampling accuracy | ±5%F.S | Pipeline flow rate | 1m/s~30m/s |

| Working temperature | -20~50 ℃ | Working humidity | 0-95%RH |

| Storage temperature | -20~50 ℃ | Pipeline pressure | -0.1 - 1MPa |

| Working current | ≤50mA | zero drift | (Time) is less than 1% of the range per year, and (temperature) is less than 1% of the range within the specified temperature range. |

| Operating voltage | DC5V±1%/DC24±1% | Baud rate | 9600 |

| Installation method | Plug-in dust detector | Warranty period | 1 year |

| Shell material | Aluminum alloy | Service life | 1 to 3 years |

| Protection level | IP66 waterproof splash and short time rain | Explosion-proof grade | E x d I IC T 6 |

| Receiving equipment | User computer, control alarm, PLC, DCS, DDC, etc. | ||

| Alarm mode | On-site sound and light alarm, external alarm, remote controller alarm, computer data acquisition software alarm, etc. | ||

| Alarm Settings | Standard configuration of two-level alarm, optional three-level alarm; alarm mode can be set: regular high and low alarm, interval control alarm | ||

| Connection cable |

① Select three-core shielded cable for 4 ~ 20mA and four-core cable for RS485. When the distance exceeds 1000 m (with a detector), the single wire diameter shall be ≥ 1.5mm, and the shielding layer shall be connected to the ground. ② wireless transmission: can be built-in LORA, Zigbeg module, short-range wireless transmission; external GPRS/4G module, remote data transmission to the cloud platform, can be viewed on the computer side and mobile phone side of the history, not limited by distance (optional) |

||

| Optional accessories |

Computer monitoring accessories: free upper computer software, USB to RS485 conversion cable, RS485 to network port converter if network transmission is required. Mounting bracket |

||

Working principle of pipeline dust concentration detector

The dust concentration detector measures the amount of electrostatic charge induced by dust particles passing through a fixed probe. The dust particles induce electrostatic charge with the probe, and the signal is amplified by the probe and transmitted into the monitoring and control system. The magnitude of the electrostatic charge is proportional to the flux of the dust particles. The high-tech electronic circuit of the system converts this part of the charge into a control signal output to start the dust emission alarm, and is used to continuously record the total amount or concentration of dust particles.

The device provides the latest AC coupling technology in the world. This is the most accurate and stable monitoring technology in modern times, especially suitable for continuous emission recording and data accumulation. The working principle of this monitoring system is to use the charge induction generated by dust particles flowing around the probe to confirm the online emission (mg/sec) or emission concentration (mg/m3) of dust particles. In the case of relatively stable combustion conditions (that is, at the same discharge point, the flow rate, temperature, pressure, humidity and soot particle properties have not changed much, less than ± 90% of the change), the system can also be used for online monitoring of emission concentration (unit = mg/M3) after direct calibration.

Application Scenarios

Petroleum and petrochemical, chemical plants, smelters, steel plants, coal plants, thermal power plants, pharmaceutical research, pharmaceutical production workshops, tobacco companies, environmental monitoring, school research, building construction, fire alarm, sewage treatment, industrial gas process control, boiler room, Garbage treatment plant, tunnel construction, oil pipeline, gas filling station, underground gas pipeline maintenance, indoor air quality inspection, safety protection in hazardous places, aerospace, military equipment monitoring, etc.

On-line dust concentration detector interface display introduction

The instrument has a total of 3 buttons, namely "add/cancel", "function/confirm", "move right/down" (hereinafter referred to as "add" ("cancel"), "function" ("confirm"), "move right" ("move left")). The three key positions are as follows. Press the "Function" button.

Internal diagram of online dust concentration detector

Installation and Precautions

The sensor is best installed in the vertical pipe, from the valve, elbow more than 5 times the diameter of the pipe, to be in the horizontal pipe sampling, shall not be installed at the bottom. For the gas dust removal system with multiple boxes running in parallel, a hole shall be opened on the pipeline before entering the net gas main pipe at the outlet of the tested dust removal box (the opening size is φ32mm), and the base interface end of the fixed sensor shall be vertically welded to the top of the horizontal pipeline with a longer straight pipe section.

② The length of the sensor probe, according to the user's need to measure the diameter of the pipe, is selected and supplied by the instrument manufacturer. The base shall be that the top of the insulating sleeve of the sensor probe is level with the inner wall of the pipeline or protrudes out of the inner wall of the pipeline. The base is supplied by the instrument manufacturer.

③ Add copper pad between the sensor and the socket, connect with screw thread and tighten to prevent the leakage of toxic gas in the pipe.

④ The sensor junction box is rainproof. The signal cable is directly connected to the connection terminal in the box through the threading hole on the junction box, and then the sealing rubber ring is compressed. The external cable should be fixed nearby to prevent it from swinging back and forth in wind and rain. Mechanical damage to the transmission wire.

Attention during installation

1. The base and length of the sensor shall be provided by the manufacturer. The opening size of the base in the pipeline shall be φ 32±2mm.

2, the transmission wire please choose 0.75mm2 -- 1.5mm2 ordinary twisted pair (in a particularly strong interference environment, please use a shielded double-core cable, and the shielding layer is well grounded).

Product Recommendation

Portable SF6 gas analyzer Sulfur hexafluoride detector-HNAG920

Portable SF6 gas analyzer Sulfur hexafluoride detector

Model: HNAG920 Sampling Method: Pumping Suction and Diffusion Detection Principle: Infrared NDIR Gas: Sulfur hexafluoride (SF6). Range: 0-1000ppm,0-3000PPM,0-5000PPM. Resolution: 1PPM. Accuracy: ≤±2% F.S.

Handheld Acetylene gas detector 0-100%LEL-HNAG920

Handheld Acetylene gas detector 0-100%LEL

Model: HNAG920 Sampling Method: Pumping Suction and Diffusion Detection Principle: Infrared NDIR Gas: Acetylene (C2H2). Range: 0-100%LEL Resolution: 0.1LEL. Accuracy: ≤±2% F.S.

Portable Methyl Bromide Gas Detector CH3Br-HNAG920

Portable Methyl Bromide Gas Detector CH3Br

Model: HNAG920 Sampling Method: Pumping Suction and Diffusion Detection Principle: PID Gas: Methyl Bromide (CH3Br). Range: 0 to 50/100/200/500/1000/2000/3000ppm Resolution: 0.01ppm;0.1ppm;1ppm. Accuracy: ≤±2% F.S.

Punp suction Portable ozone sensor detector-HNAG920

Punp suction Portable ozone sensor detector

Model: HNAG920 Sampling Method: Pumping Suction and Diffusion Detection Principle:Electrochemistry Gas: ozone (O3) Range: 0-50PPM,0-100PPM. Resolution: 0.01PPM,0.1PPM. Accuracy: ≤±2% F.S.

Handheld SF6 gas detector Sulfur hexafluoride analyzer-HNAG900

Handheld SF6 gas detector Sulfur hexafluoride analyzer

Model: HNAG900 Sampling Method: Pumping Suction and Diffusion Detection Principle: Infrared NDIR Gas: Sulfur hexafluoride (SF6). Range: 0-1000ppm,0-3000PPM,0-5000PPM. Resolution: 1PPM. Accuracy: ≤±2% F.S.

Handheld Chlorine Dioxide analyzer CLO2-HNAG900

Handheld Chlorine Dioxide analyzer CLO2

Model: HNAG900 Sampling Method: Pumping Suction Detection Principle: Electrochemistry Gas: Chlorine Dioxide/CLO2 Range: 0-10ppm;0-1ppm. Resolution: 0.01PPM. Accuracy: ≤±2% F.S.

Handheld Formaldehyde gas detector CH2O-HNAG900

Handheld Formaldehyde gas detector CH2O

Model: HNAG900 Sampling Method: Pumping Suction Detection Principle:Electrochemistry Gas: Formaldehyde (CH2O) Range: 0-50PPM,0-100PPM. Resolution: 0.01PPM,0.1PPM. Accuracy: ≤±2% F.S.

Handheld nitrogen gas detector 0-100%vol-HNAG920

Handheld nitrogen gas detector 0-100%vol

Model: HNAG920 Sampling Method: Pumping Suction Detection Principle: Electrochemistry Gas: N2 Range: 0-100%vol Resolution: 1%vol. Accuracy: ≤±2% F.S.

Trending pump suction diffusion portable combustible gas detector co co2 no no2 toxic gas detector Wireless transmission for Underground pipeline Sewage well Cabin-

Trending pump suction diffusion portable combustible gas detector co co2 no no2 toxic gas detector Wireless transmission for Underground pipeline Sewage well Cabin

Category: Products Portable gas detector Portable gas detector Key words: Products Model: HNAG920 Measurement object: CO2/Ex/CH4/CO/H2S/O2/N2/NH3/CL2/H2/He/Ar/CH2O/O3/NO/NO2/SO2/C2H4O/PH3/COCL2/HBR/HCL/HCN/CLO2/SIH4/CH3BR/SO2F2/F2/HF/C2H2/CS2/SF6/C2H...

Combustible Online Gas Detector LEL Alarm Monitor System-SK/MIC-600

Combustible Online Gas Detector LEL Alarm Monitor System

Detection gas:EX_Flammable-CH4 Range:0-100%LEL (3-100%LEL) / 0-5%VOL Detection Principle:Infrared Resolution:0.1%LEL_0.001%VOL Detection Accuracy:±2%F.S Model:SK/MIC-600

Intrinsically Safe Carbon Monoxide Detector with Explosion Proof-HNAG1000

Intrinsically Safe Carbon Monoxide Detector with Explosion Proof

Detection gas:CO,Carbon monoxide Range:0-1000ppm/0-5000ppm/custom Detection Principle:Electrochemistry Resolution:1ppm Detection Accuracy:±2%F.S Model:HNAG1000

Fixed carbon monoxide detector RS485 4-20mA-HNAG1000

Fixed carbon monoxide detector RS485 4-20mA

Detection gas:CO,Carbon monoxide Range:0-1000ppm/0-5000ppm/custom Detection Principle:Electrochemistry Resolution:1ppm Detection Accuracy:±2%F.S Model:HNAG1000

Portable Oxygen gas detector alarm 0-30%vol gas monitoring-HNAG920-O2

Portable Oxygen gas detector alarm 0-30%vol gas monitoring

Detection gas:O2/Oxygen Range:0-30%VOL (0-25%VOL) / 0-100%VOL Detection Principle:Electrochemistry Resolution:0.1%VOL/0.01%VOL Detection Accuracy:±2%F.S Model:HNAG920

industrial gas detector o2 pump suction Oxygen analyzer-HNAG920-O2

industrial gas detector o2 pump suction Oxygen analyzer

Detection gas:O2/Oxygen Range:0-30%VOL (0-25%VOL) / 0-100%VOL Detection Principle:Electrochemistry Resolution:0.1%VOL/0.01%VOL Detection Accuracy:±2%F.S Model:HNAG920

Multi-gas Integrated Pretreatment Online Monitoring System Toxic Gas Analyzer RTO Leak-proof Detection Alarm Instrument-SK/MIC-7500

Multi-gas Integrated Pretreatment Online Monitoring System Toxic Gas Analyzer RTO Leak-proof Detection Alarm Instrument

Category: Products Flue gas pretreatment system Simple Pretreatment Online Monitoring System Key words: Products Model: SK/MIC-7500 Measurement object: CO2/Ex/CH4/CO/H2S/O2/N2/NH3/CL2/H2/He/Ar/CH2O/O3/NO/NO2/SO2/C2H4O/PH3/COCL2/HBR/HCL/HCN/CLO2/SIH4/...

handheld helium leak detector He analyzer-HNAG900

handheld helium leak detector He analyzer

Model: HNAG900 Sampling Method: Pumping Suction Detection Principle: Thermal conductivity Gas: helium (He) Range: 0-100%vol Resolution: 1%vol. Accuracy: ≤±2% F.S.

Handheld ozone detector O3 monitor-HNAG900

Handheld ozone detector O3 monitor

Model: HNAG900 Sampling Method: Pumping Suction Detection Principle:Electrochemistry Gas: ozone (O3) Range: 0-50PPM,0-100PPM. Resolution: 0.01PPM,0.1PPM. Accuracy: ≤±2% F.S.

handheld Hydrogen Fluoride gas detector HF-HNAG920

handheld Hydrogen Fluoride gas detector HF

Model: HNAG920 Sampling Method: Pumping Suction Detection Principle: Electrochemistry Gas: Hydrogen Fluoride (HF) Range: 0-10ppm,0-50ppm,0-100ppm Resolution: 0.01ppm,0.1ppm. Accuracy: ≤±2% F.S.

Portable Ethanol analyzer C2H6O ppm-HNAG920

Portable Ethanol analyzer C2H6O ppm

Model: HNAG920 Sampling Method: Pumping Suction and Diffusion Detection Principle: Electrochemistry Gas: Ethanol(C2H6O) Range: 0-10ppm,0-50ppm,0-100ppm,Custom Resolution: 0.01ppm,0.1ppm,1ppm. Accuracy: ≤±2% F.S.

Pump suction portable Ethylene gas detector C2H4 0-100ppm-HNAG920

Pump suction portable Ethylene gas detector C2H4 0-100ppm

Model: HNAG920 Sampling Method: Pumping Suction and Diffusion Detection Principle: Electrochemistry Gas: Ethylene (C2H4) Range: 0-10ppm,0-50ppm,0-100ppm,0-200ppm. Resolution: 0.01ppm,0.1ppm. Accuracy: ≤±2% F.S.

Portable SF6 gas analyzer Sulfur hexafluoride detector-HNAG920

Portable SF6 gas analyzer Sulfur hexafluoride detector

Model: HNAG920 Sampling Method: Pumping Suction and Diffusion Detection Principle: Infrared NDIR Gas: Sulfur hexafluoride (SF6). Range: 0-1000ppm,0-3000PPM,0-5000PPM. Resolution: 1PPM. Accuracy: ≤±2% F.S.

Handheld Acetylene gas detector 0-100%LEL-HNAG920

Handheld Acetylene gas detector 0-100%LEL

Model: HNAG920 Sampling Method: Pumping Suction and Diffusion Detection Principle: Infrared NDIR Gas: Acetylene (C2H2). Range: 0-100%LEL Resolution: 0.1LEL. Accuracy: ≤±2% F.S.

Portable Methyl Bromide Gas Detector CH3Br-HNAG920

Portable Methyl Bromide Gas Detector CH3Br

Model: HNAG920 Sampling Method: Pumping Suction and Diffusion Detection Principle: PID Gas: Methyl Bromide (CH3Br). Range: 0 to 50/100/200/500/1000/2000/3000ppm Resolution: 0.01ppm;0.1ppm;1ppm. Accuracy: ≤±2% F.S.

Punp suction Portable ozone sensor detector-HNAG920

Punp suction Portable ozone sensor detector

Model: HNAG920 Sampling Method: Pumping Suction and Diffusion Detection Principle:Electrochemistry Gas: ozone (O3) Range: 0-50PPM,0-100PPM. Resolution: 0.01PPM,0.1PPM. Accuracy: ≤±2% F.S.

Handheld SF6 gas detector Sulfur hexafluoride analyzer-HNAG900

Handheld SF6 gas detector Sulfur hexafluoride analyzer

Model: HNAG900 Sampling Method: Pumping Suction and Diffusion Detection Principle: Infrared NDIR Gas: Sulfur hexafluoride (SF6). Range: 0-1000ppm,0-3000PPM,0-5000PPM. Resolution: 1PPM. Accuracy: ≤±2% F.S.

Handheld Chlorine Dioxide analyzer CLO2-HNAG900

Handheld Chlorine Dioxide analyzer CLO2

Model: HNAG900 Sampling Method: Pumping Suction Detection Principle: Electrochemistry Gas: Chlorine Dioxide/CLO2 Range: 0-10ppm;0-1ppm. Resolution: 0.01PPM. Accuracy: ≤±2% F.S.

Handheld Formaldehyde gas detector CH2O-HNAG900

Handheld Formaldehyde gas detector CH2O

Model: HNAG900 Sampling Method: Pumping Suction Detection Principle:Electrochemistry Gas: Formaldehyde (CH2O) Range: 0-50PPM,0-100PPM. Resolution: 0.01PPM,0.1PPM. Accuracy: ≤±2% F.S.

Handheld nitrogen gas detector 0-100%vol-HNAG920

Handheld nitrogen gas detector 0-100%vol

Model: HNAG920 Sampling Method: Pumping Suction Detection Principle: Electrochemistry Gas: N2 Range: 0-100%vol Resolution: 1%vol. Accuracy: ≤±2% F.S.

Trending pump suction diffusion portable combustible gas detector co co2 no no2 toxic gas detector Wireless transmission for Underground pipeline Sewage well Cabin-

Trending pump suction diffusion portable combustible gas detector co co2 no no2 toxic gas detector Wireless transmission for Underground pipeline Sewage well Cabin

Category: Products Portable gas detector Portable gas detector Key words: Products Model: HNAG920 Measurement object: CO2/Ex/CH4/CO/H2S/O2/N2/NH3/CL2/H2/He/Ar/CH2O/O3/NO/NO2/SO2/C2H4O/PH3/COCL2/HBR/HCL/HCN/CLO2/SIH4/CH3BR/SO2F2/F2/HF/C2H2/CS2/SF6/C2H...

Combustible Online Gas Detector LEL Alarm Monitor System-SK/MIC-600

Combustible Online Gas Detector LEL Alarm Monitor System

Detection gas:EX_Flammable-CH4 Range:0-100%LEL (3-100%LEL) / 0-5%VOL Detection Principle:Infrared Resolution:0.1%LEL_0.001%VOL Detection Accuracy:±2%F.S Model:SK/MIC-600

Intrinsically Safe Carbon Monoxide Detector with Explosion Proof-HNAG1000

Intrinsically Safe Carbon Monoxide Detector with Explosion Proof

Detection gas:CO,Carbon monoxide Range:0-1000ppm/0-5000ppm/custom Detection Principle:Electrochemistry Resolution:1ppm Detection Accuracy:±2%F.S Model:HNAG1000

Fixed carbon monoxide detector RS485 4-20mA-HNAG1000

Fixed carbon monoxide detector RS485 4-20mA

Detection gas:CO,Carbon monoxide Range:0-1000ppm/0-5000ppm/custom Detection Principle:Electrochemistry Resolution:1ppm Detection Accuracy:±2%F.S Model:HNAG1000

Portable Oxygen gas detector alarm 0-30%vol gas monitoring-HNAG920-O2

Portable Oxygen gas detector alarm 0-30%vol gas monitoring

Detection gas:O2/Oxygen Range:0-30%VOL (0-25%VOL) / 0-100%VOL Detection Principle:Electrochemistry Resolution:0.1%VOL/0.01%VOL Detection Accuracy:±2%F.S Model:HNAG920

industrial gas detector o2 pump suction Oxygen analyzer-HNAG920-O2

industrial gas detector o2 pump suction Oxygen analyzer

Detection gas:O2/Oxygen Range:0-30%VOL (0-25%VOL) / 0-100%VOL Detection Principle:Electrochemistry Resolution:0.1%VOL/0.01%VOL Detection Accuracy:±2%F.S Model:HNAG920

Give us a free quote

Submit this form and our sales representative will contact you soon.