VOC Monitoring System Deployment

Release time:2026-01-29

Source:Skyealgee

VOC Monitoring System Deployment for Oil & Gas Processing Skid

Challenge: Mitigate Volatile Organic Compounds (VOC) leakage risks in Zone 1 explosive hazardous areas, while meeting local safety regulations.

The client’s well test skid handles high-pressure crude oil and associated gas, where Volatile Organic Compounds (VOCs) such as benzene and toluene are continuously released at pipe joints, flange seals, and valve connections. Prior to the upgrade, the site relied on manual inspections, which failed to detect minor leaks in real time and exposed operators to toxic VOC exposure risks. To address this, the site required a robust monitoring solution combining fixed and portable devices.

Solution Implementation

The engineering team designed a layered monitoring system tailored to the skid’s layout:

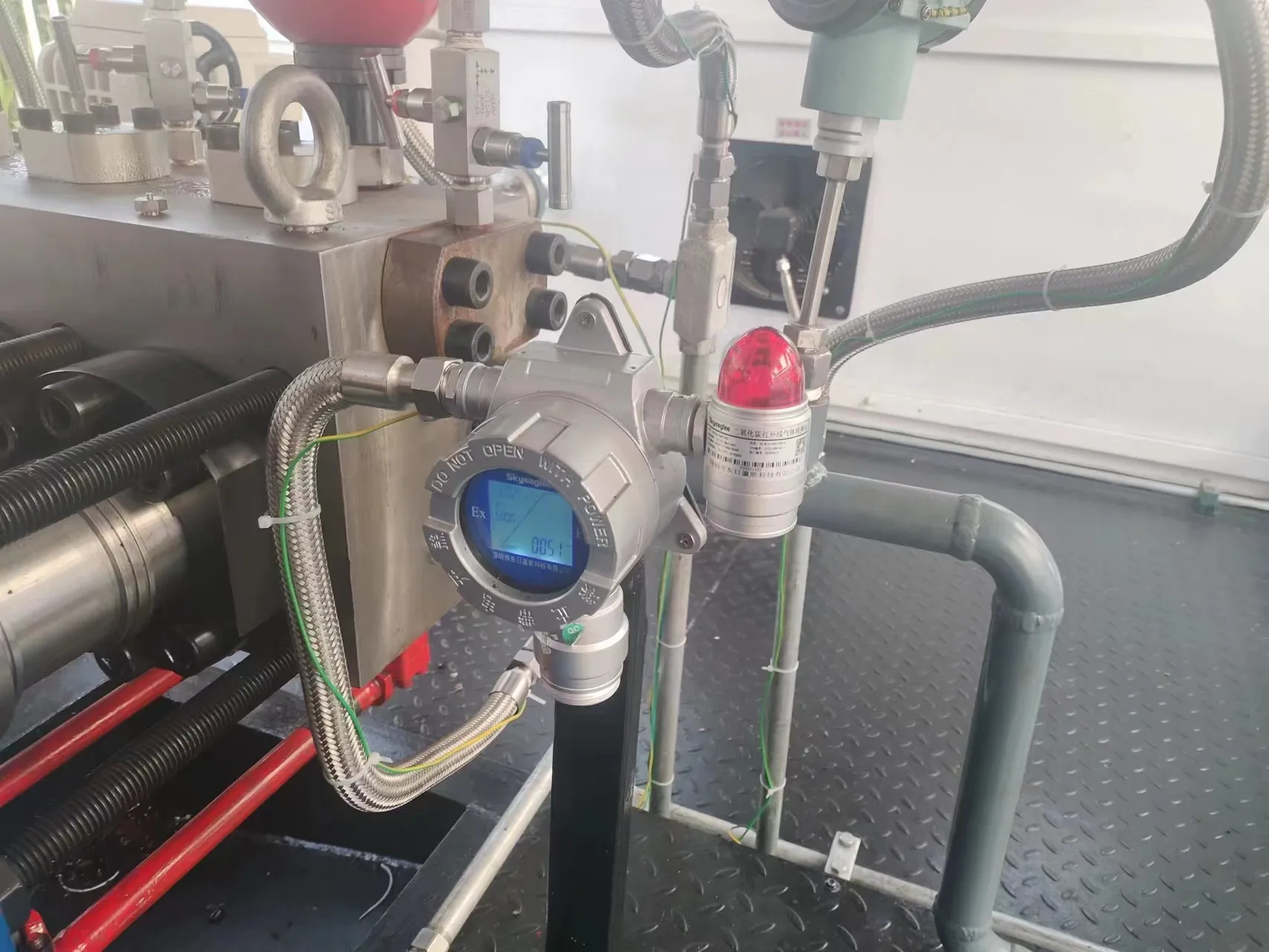

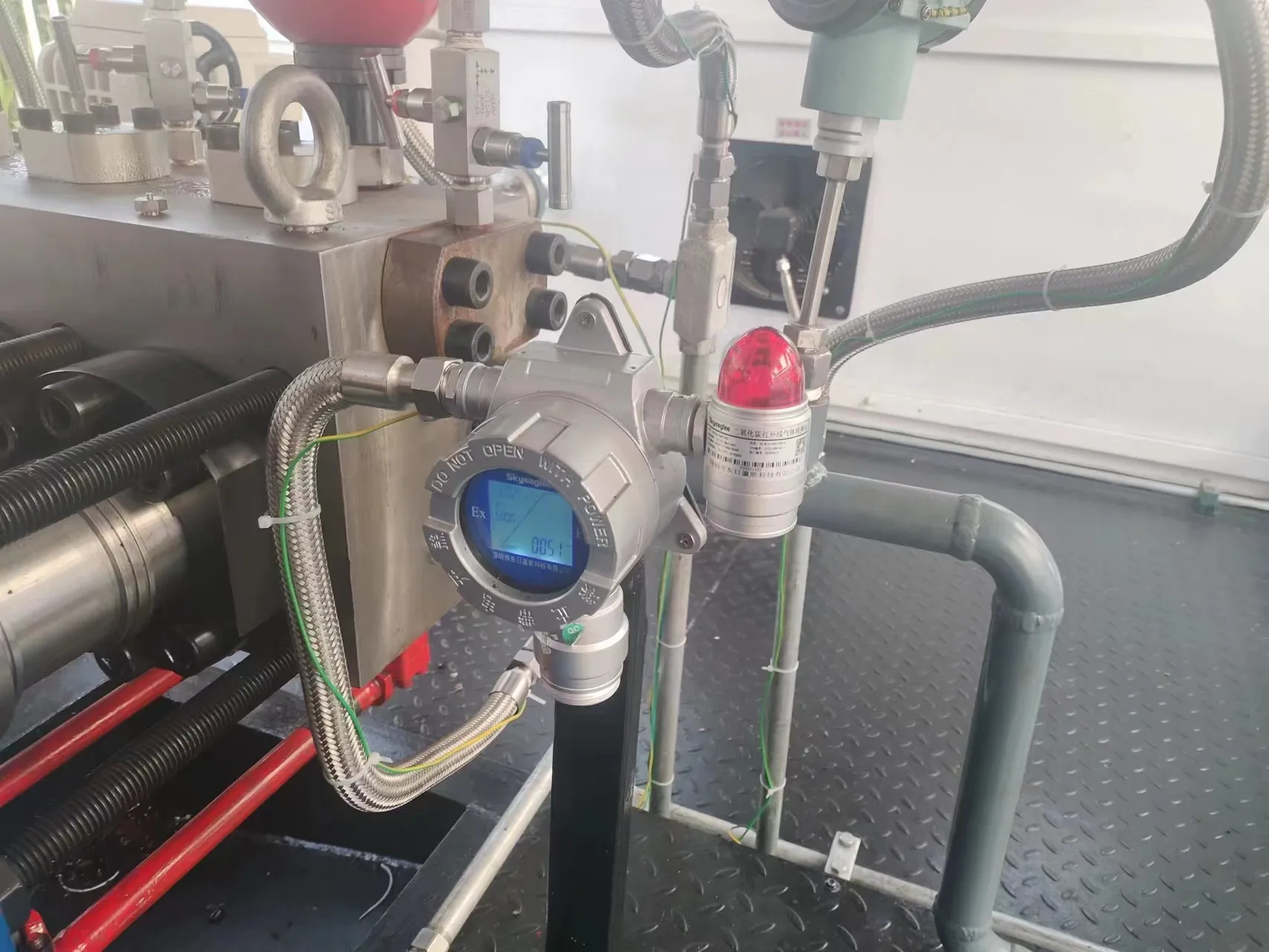

Fixed VOC Gas Detector Installation

We installed 8 fixed VOC gas detectors, each equipped with a high-sensitivity Volatile Organic Compounds sensor (PID principle) and ATEX/IECEx explosion-proof certification, at critical leakage points (e.g., pipeline junctions and pressure relief valves). The VOC sensor in each unit features anti-fouling filters to resist dust and oil contamination from the skid’s mechanical vibration, ensuring stable long-term operation.

Portable & Handheld Complementary Monitoring

For daily patrols and targeted leak verification, the team deployed:

Handheld VOC gas detector: Compact, intrinsically safe devices with built-in Volatile Organic Compounds detector modules, allowing operators to perform spot checks in confined spaces.

Gas analyzer portable: A lab-grade instrument for on-site quantitative analysis of VOC components, used to validate fixed detector data and trace leak sources.

Outcomes & Benefits

Real-Time Leak Detection: Within 3 weeks of deployment, the fixed VOC gas detector triggered an alarm for a minor flange seal leak. The handheld VOC gas detector confirmed the leak location, and maintenance teams resolved the issue before VOC concentrations reached the explosive limit.

VOC emission control, with 24/7 data logging that simplified annual safety audits.

Operational Safety: By eliminating blind spots in manual inspections, the Volatile Organic Compounds sensor network reduced operator exposure to toxic VOCs by 68% over 6 months.

Conclusion

This project demonstrates how combining a fixed VOC gas detector network with portable tools like the gas analyzer portable and handheld VOC gas detector creates a comprehensive safety barrier in explosive industrial environments. Regular calibration of the VOC sensor and routine maintenance of the detection system remain critical to sustaining performance.

FAQ:

Q1: Should I choose a Fixed VOC gas detector, a handheld VOC gas detector, or both for my well test skid?

A: We strongly recommend a combined solution. A Fixed VOC gas detector network with integrated Volatile Organic Compounds sensor provides 24/7 real-time monitoring of high-risk points like flanges and pipe joints. A handheld VOC gas detector is essential for daily patrols, leak localization, and verifying fixed detector alarms. For precise component analysis, a gas analyzer portable can be added to validate VOC composition and trace leak sources.

Q2: What type of VOC sensor is best for high-vibration, oil-contaminated oil & gas skid environments?

A: A PID (Photoionization Detector) Volatile Organic Compounds sensor is the most suitable choice. It offers high sensitivity to VOCs like benzene and toluene, and can be equipped with anti-fouling filters to resist dust and oil contamination. Ensure the sensor is housed in a rugged, explosion-proof enclosure to withstand mechanical vibration.

Q3: What explosion-proof certifications are required for a Volatile Organic Compounds detector in Zone 1 hazardous areas?

A: For Zone 1 explosive environments, your Volatile Organic Compounds detector must hold ATEX/IECEx Ex ia IIC T4 or GB Ex ia IIC T4 certification. This ensures the device cannot ignite flammable gases, even if it malfunctions.

Q4: What’s the difference between a gas analyzer portable and a handheld VOC gas detector? Do I need both?

A: A handheld VOC gas detector is designed for fast, qualitative leak checks and general VOC level monitoring. A gas analyzer portable is a lab-grade tool for quantitative analysis of specific VOC components (e.g., benzene, hexane). For routine patrols, a handheld device is sufficient; a portable analyzer is only necessary for compliance audits or precise leak source tracing.

VOC Monitoring System Deployment for Oil & Gas Processing Skid

Challenge: Mitigate Volatile Organic Compounds (VOC) leakage risks in Zone 1 explosive hazardous areas, while meeting local safety regulations.

Project Background

The client’s well test skid handles high-pressure crude oil and associated gas, where Volatile Organic Compounds (VOCs) such as benzene and toluene are continuously released at pipe joints, flange seals, and valve connections. Prior to the upgrade, the site relied on manual inspections, which failed to detect minor leaks in real time and exposed operators to toxic VOC exposure risks. To address this, the site required a robust monitoring solution combining fixed and portable devices.

Solution Implementation

The engineering team designed a layered monitoring system tailored to the skid’s layout:

Fixed VOC Gas Detector Installation

We installed 8 fixed VOC gas detectors, each equipped with a high-sensitivity Volatile Organic Compounds sensor (PID principle) and ATEX/IECEx explosion-proof certification, at critical leakage points (e.g., pipeline junctions and pressure relief valves). The VOC sensor in each unit features anti-fouling filters to resist dust and oil contamination from the skid’s mechanical vibration, ensuring stable long-term operation.

Portable & Handheld Complementary Monitoring

For daily patrols and targeted leak verification, the team deployed:

Handheld VOC gas detector: Compact, intrinsically safe devices with built-in Volatile Organic Compounds detector modules, allowing operators to perform spot checks in confined spaces.

Gas analyzer portable: A lab-grade instrument for on-site quantitative analysis of VOC components, used to validate fixed detector data and trace leak sources.

Outcomes & Benefits

Real-Time Leak Detection: Within 3 weeks of deployment, the fixed VOC gas detector triggered an alarm for a minor flange seal leak. The handheld VOC gas detector confirmed the leak location, and maintenance teams resolved the issue before VOC concentrations reached the explosive limit.

VOC emission control, with 24/7 data logging that simplified annual safety audits.

Operational Safety: By eliminating blind spots in manual inspections, the Volatile Organic Compounds sensor network reduced operator exposure to toxic VOCs by 68% over 6 months.

Conclusion

This project demonstrates how combining a fixed VOC gas detector network with portable tools like the gas analyzer portable and handheld VOC gas detector creates a comprehensive safety barrier in explosive industrial environments. Regular calibration of the VOC sensor and routine maintenance of the detection system remain critical to sustaining performance.

FAQ:

Q1: Should I choose a Fixed VOC gas detector, a handheld VOC gas detector, or both for my well test skid?

A: We strongly recommend a combined solution. A Fixed VOC gas detector network with integrated Volatile Organic Compounds sensor provides 24/7 real-time monitoring of high-risk points like flanges and pipe joints. A handheld VOC gas detector is essential for daily patrols, leak localization, and verifying fixed detector alarms. For precise component analysis, a gas analyzer portable can be added to validate VOC composition and trace leak sources.

Q2: What type of VOC sensor is best for high-vibration, oil-contaminated oil & gas skid environments?

A: A PID (Photoionization Detector) Volatile Organic Compounds sensor is the most suitable choice. It offers high sensitivity to VOCs like benzene and toluene, and can be equipped with anti-fouling filters to resist dust and oil contamination. Ensure the sensor is housed in a rugged, explosion-proof enclosure to withstand mechanical vibration.

Q3: What explosion-proof certifications are required for a Volatile Organic Compounds detector in Zone 1 hazardous areas?

A: For Zone 1 explosive environments, your Volatile Organic Compounds detector must hold ATEX/IECEx Ex ia IIC T4 or GB Ex ia IIC T4 certification. This ensures the device cannot ignite flammable gases, even if it malfunctions.

Q4: What’s the difference between a gas analyzer portable and a handheld VOC gas detector? Do I need both?

A: A handheld VOC gas detector is designed for fast, qualitative leak checks and general VOC level monitoring. A gas analyzer portable is a lab-grade tool for quantitative analysis of specific VOC components (e.g., benzene, hexane). For routine patrols, a handheld device is sufficient; a portable analyzer is only necessary for compliance audits or precise leak source tracing.

no data