Sulfuric acid mist and phosphoric acid mist pretreatment analyzer plan

Release time:2024-04-18

Source:ㅤ

Sulfuric acid mist occurs not only in factories that directly produce or use sulfuric acid, but also from factories that use coal, petroleum or heavy oil as raw materials and fuel. After the sulfur dioxide gas in the exhaust smoke turns into sulfur trioxide, it combines with the moisture in the air to form sulfuric acid mist. Sulfuric acid mist is an important secondary pollutant. Mainly derived from the industrial production process of sulfuric acid. Sulfur dioxide is oxidized in the atmosphere to sulfur trioxide, which combines with water in the air to form sulfuric acid.

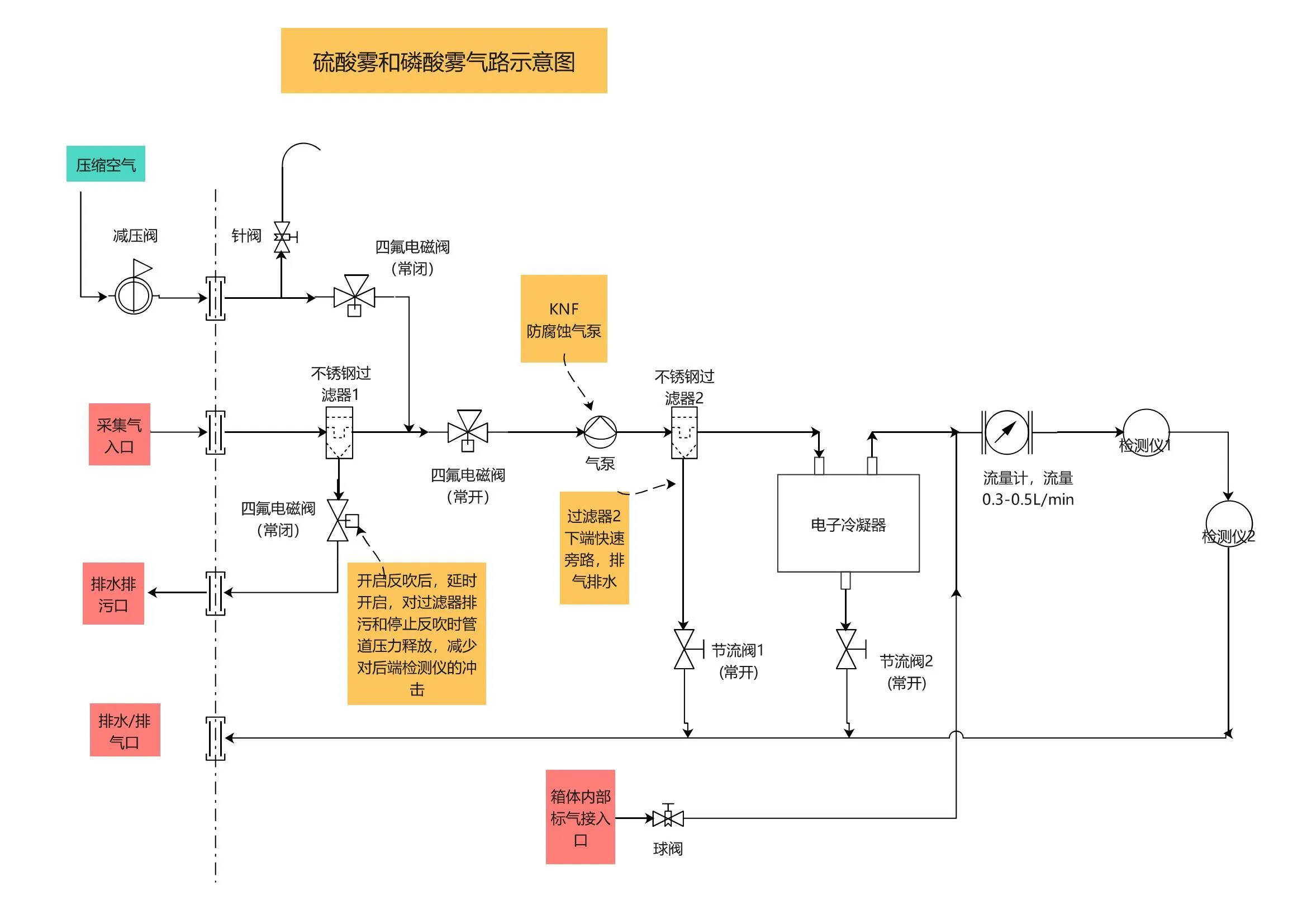

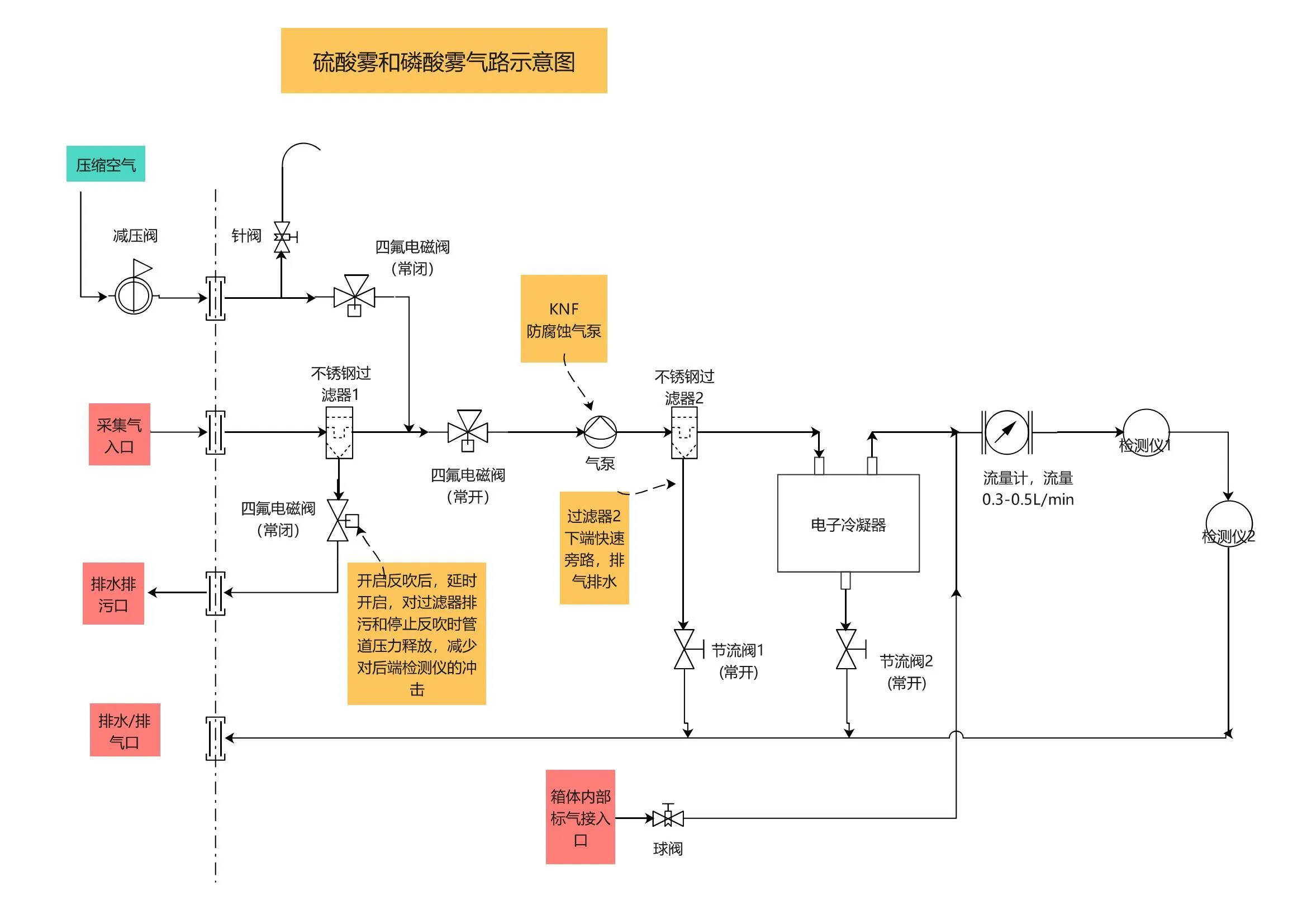

In response to the on-site reaction that the exhaust pipe contains dust and water vapor, detect sulfuric acid mist and phosphoric acid mist.

Measures to be taken:

1. The analyzer box is made of anti-corrosion stainless steel and most of the gas paths are made of stainless steel. Only the air pump and the four-gas solenoid valve joint transfer part are made of PTFE. The electrical interface is made of stainless steel. The internal positive pressure vent is explosion-proof. net.

2. Install the sampling probe fixed at the pipe flange, extend the front end to the middle of the center of the pipe, bend the front end of the sampling head downward at a certain angle and make a small incision.

3. Use PTFE pipes to connect the sampling flange to the air inlet of the analyzer box and the drain outlet to the return point.

4. The internal joint parts of the box are made of stainless steel; the pipes are made of PTFE pipes. The components used should be protected against acid and alkali corrosion.

5. There is a compressed gas positive pressure box design inside the box, and the air is discharged out in real time, reducing the risk of hydrogen leakage and accumulation.

6. There are 2-way filters inside, with redundant design for dust filtration and drainage.

7. When the concentration at the collection point changes rapidly, there is a fast bypass, faster response, and the condenser has high condensation and water removal efficiency.

8. Automatic control of backflush and normal detection, adjustable intermittent drainage or real-time drainage. Optional liquid level detection can be added to realize active drainage (to deal with emergencies of large amounts of water).

The advantages are: 1. The air pressure inside the box is positive, and there is no accumulation of flammable gas inside, making it safer. 2. Drainage is more reliable and has design redundancy. Up to 3 channels of drainage, peristaltic pump damage redundant design. a. The drainage peristaltic pump can drain water regularly and in real time. Even if it is damaged, it has a redundant design of the air circuit function controlled by the solenoid valve 2. The solenoid valve 2 is opened for drainage during scheduled backflush. b. Even if the peristaltic pump and solenoid valve 2 are not enough to cope with drainage, the lower end of filter 2 can drain water under positive pressure. c. The lower end of the condenser can ensure the drainage of water condensed by the condenser. 3. High water removal efficiency. After the drainage of the front filter 1 and the rapid bypass exhaust drainage at the lower end of the filter 2, a small amount of gas enters the condenser, and the water removal efficiency is high.

(1) Connect the compressed air, and use the compressed air to backflush by controlling the solenoid valve.

(2) During backflush, the solenoid valve at the lower end of filter 1 can be opened with a delay to discharge dust or other impurities in the filter and release the backflush pressure in the air path to reduce the impact on the back-end detector. Airway impact.

(3) Double filters also have a redundant design. Dust and water vapor are discharged from filter 1. Filter 2 can be used as a quick response bypass for the air intake. If filter 1 is full of water and overflows, it can be corrected under filter 2. Press the pressure to drain away.

(4) A small amount of gas that needs to be detected enters the electronic condenser, condenses and removes water, then enters the flow meter to control the flow, and then enters the detector for detection.

Sulfuric acid mist occurs not only in factories that directly produce or use sulfuric acid, but also from factories that use coal, petroleum or heavy oil as raw materials and fuel. After the sulfur dioxide gas in the exhaust smoke turns into sulfur trioxide, it combines with the moisture in the air to form sulfuric acid mist. Sulfuric acid mist is an important secondary pollutant. Mainly derived from the industrial production process of sulfuric acid. Sulfur dioxide is oxidized in the atmosphere to sulfur trioxide, which combines with water in the air to form sulfuric acid.

In response to the on-site reaction that the exhaust pipe contains dust and water vapor, detect sulfuric acid mist and phosphoric acid mist.

Measures to be taken:

1. The analyzer box is made of anti-corrosion stainless steel and most of the gas paths are made of stainless steel. Only the air pump and the four-gas solenoid valve joint transfer part are made of PTFE. The electrical interface is made of stainless steel. The internal positive pressure vent is explosion-proof. net.

2. Install the sampling probe fixed at the pipe flange, extend the front end to the middle of the center of the pipe, bend the front end of the sampling head downward at a certain angle and make a small incision.

3. Use PTFE pipes to connect the sampling flange to the air inlet of the analyzer box and the drain outlet to the return point.

4. The internal joint parts of the box are made of stainless steel; the pipes are made of PTFE pipes. The components used should be protected against acid and alkali corrosion.

5. There is a compressed gas positive pressure box design inside the box, and the air is discharged out in real time, reducing the risk of hydrogen leakage and accumulation.

6. There are 2-way filters inside, with redundant design for dust filtration and drainage.

7. When the concentration at the collection point changes rapidly, there is a fast bypass, faster response, and the condenser has high condensation and water removal efficiency.

8. Automatic control of backflush and normal detection, adjustable intermittent drainage or real-time drainage. Optional liquid level detection can be added to realize active drainage (to deal with emergencies of large amounts of water).

The advantages are: 1. The air pressure inside the box is positive, and there is no accumulation of flammable gas inside, making it safer. 2. Drainage is more reliable and has design redundancy. Up to 3 channels of drainage, peristaltic pump damage redundant design. a. The drainage peristaltic pump can drain water regularly and in real time. Even if it is damaged, it has a redundant design of the air circuit function controlled by the solenoid valve 2. The solenoid valve 2 is opened for drainage during scheduled backflush. b. Even if the peristaltic pump and solenoid valve 2 are not enough to cope with drainage, the lower end of filter 2 can drain water under positive pressure. c. The lower end of the condenser can ensure the drainage of water condensed by the condenser. 3. High water removal efficiency. After the drainage of the front filter 1 and the rapid bypass exhaust drainage at the lower end of the filter 2, a small amount of gas enters the condenser, and the water removal efficiency is high.

(1) Connect the compressed air, and use the compressed air to backflush by controlling the solenoid valve.

(2) During backflush, the solenoid valve at the lower end of filter 1 can be opened with a delay to discharge dust or other impurities in the filter and release the backflush pressure in the air path to reduce the impact on the back-end detector. Airway impact.

(3) Double filters also have a redundant design. Dust and water vapor are discharged from filter 1. Filter 2 can be used as a quick response bypass for the air intake. If filter 1 is full of water and overflows, it can be corrected under filter 2. Press the pressure to drain away.

(4) A small amount of gas that needs to be detected enters the electronic condenser, condenses and removes water, then enters the flow meter to control the flow, and then enters the detector for detection.

ㅤ

ㅤ