Online monitoring scheme for oxygen content in reactor and oxygen content in centrifuge

Release time:2024-04-18

Source:ㅤ

As a kind of industrial equipment, reactor centrifuge is used in petroleum, chemical industry and other fields.Almost all of these industries have explosion-proof requirements for reactor centrifuges. Centrifuge safety issues have become the primary concern of pharmaceutical factories.

As we all know, combustion requires three elements, combustibles, combustion accelerants, and ignition points. The essence of explosion prevention is to control these three elements. Oxygen, as a chemically active gas, is also a very common combustion accelerant. In the petroleum, chemical, pharmaceutical and other industries, the materials fed to reactor centrifuges are mostly flammable and explosive substances, so it is particularly important to control the oxygen content inside the reactor centrifuge. It is necessary to analyze the oxygen content in the reactor centrifuge cavity. How to measure the oxygen content in the process gas quickly, reliably and with low maintenance has always been an important topic. There are currently two common measures in the industry.

One is the inert gas replacement method:

This method mainly ensures that the oxygen content in the reactor is maintained low by continuously injecting inert gas into the reactor. However, this method also has a big limitation. There is no quantitative control on whether the concentration of inert gas injected into the reactor centrifuge can reach a safe range. There is no clear numerical value as a basis, and it is impossible to deal with various unexpected factors in the feeding. Control, therefore, has poor reliability of protection.

The second is the oxygen content monitoring method:

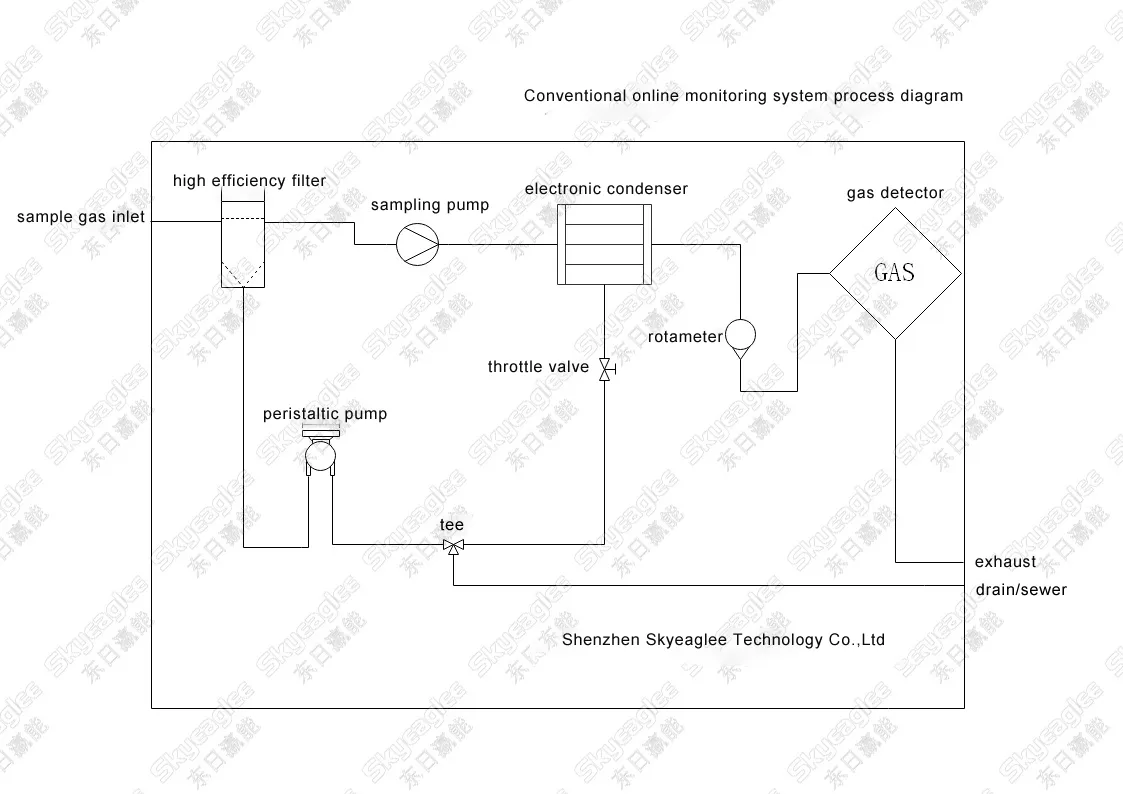

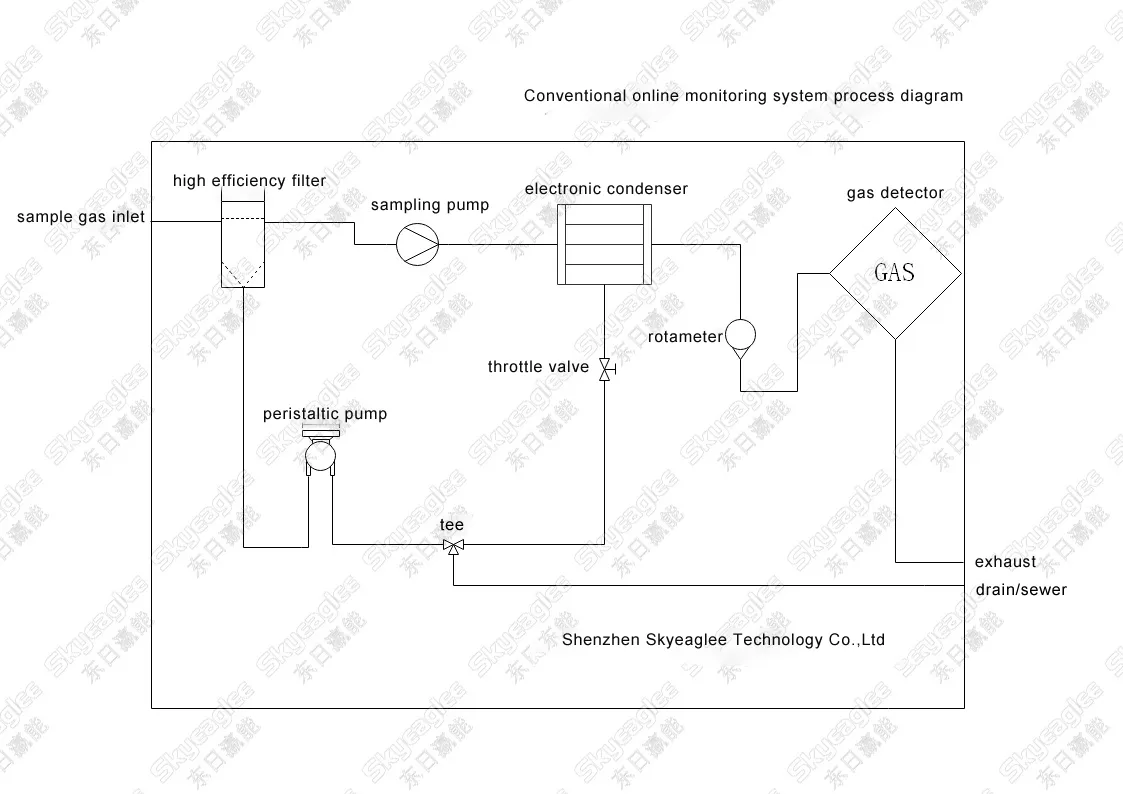

By installing the reactor oxygen content online analysis system and the centrifuge oxygen content analysis system, the oxygen content in the reactor centrifuge can be monitored online in real time. The principle is to pump a certain amount of gas from the reactor to the analytical instrument through a pipeline to monitor the oxygen content in the reactor centrifuge online in real time, and you can set the concentration alarm value yourself. When the oxygen content reaches the alarm threshold, the analyzer will automatically alarm . Compared with the inert gas replacement method, the online analysis system for online monitoring of the oxygen content in the reactor has very obvious advantages. It fundamentally solves the problem of monitoring the oxygen concentration inside the reactor. However, the shortcomings are also obvious. This is mainly due to different industries and manufacturers. The reactor centrifuge has different feeding materials and different parameters. It needs to be personalized and there is no universal solution. Corresponding pretreatment systems need to be developed for different process parameters.

For example, if the gas in the reactor centrifuge contains corrosive gases, excessive water content, etc., it needs to be pretreated in advance before it can be monitored through the reactor oxygen content online analysis system. At present, this method is mainly adopted by centrifuge manufacturers or terminals are modified by themselves.

Selection of reactor oxygen content online analysis system and centrifuge oxygen content analysis system:

There are usually many methods for detecting oxygen content, such as traditional electrochemistry, ion current, paramagnetic, zirconium oxide, laser and other principles. Generally speaking, special working conditions are treated specially. The gas composition in the centrifuge chamber of the reactor is not complicated. When dealing with corrosive gases, strong acids and alkaline gases, a general electrochemical oxygen analyzer can be considered. The electrochemical principle has good versatility and low price. The disadvantage is that the sensor is not corrosion-resistant and cannot be used directly when there are corrosive or acidic and alkaline gases. It must pass through a pretreatment system before oxygen content analysis can be performed.

When the gas composition in the reactor centrifuge chamber is complex, such as acidic gas (acetic acid), alkaline gas or water vapor, etc., oxygen analyzers using traditional methods such as electrochemistry not only require a complex pretreatment system, but also have poor performance. Relatively poor, a magnetic oxygen analyzer or laser oxygen analyzer is generally recommended under such working conditions.

Because the paramagnetic oxygen analyzer uses physical principles (note: electrochemistry is a chemical principle) to measure oxygen content, it only needs simple preprocessing. It can be installed in direct pipelines and can accept acidic gases and alkaline gases. The influence of water vapor and water vapor is small, and the oxygen content is directly monitored.

In addition to electrochemical oxygen analyzers and magnetic oxygen analyzers, there are also laser oxygen analysis systems. Like magnetic oxygen, laser oxygen uses optical principles to measure oxygen content and is not sensitive to acidic, alkaline, corrosive and other gases. The only real disadvantage is that it has requirements for the content of dust and other particulate matter in the measured gas.

As a kind of industrial equipment, reactor centrifuge is used in petroleum, chemical industry and other fields.Almost all of these industries have explosion-proof requirements for reactor centrifuges. Centrifuge safety issues have become the primary concern of pharmaceutical factories.

As we all know, combustion requires three elements, combustibles, combustion accelerants, and ignition points. The essence of explosion prevention is to control these three elements. Oxygen, as a chemically active gas, is also a very common combustion accelerant. In the petroleum, chemical, pharmaceutical and other industries, the materials fed to reactor centrifuges are mostly flammable and explosive substances, so it is particularly important to control the oxygen content inside the reactor centrifuge. It is necessary to analyze the oxygen content in the reactor centrifuge cavity. How to measure the oxygen content in the process gas quickly, reliably and with low maintenance has always been an important topic. There are currently two common measures in the industry.

One is the inert gas replacement method:

This method mainly ensures that the oxygen content in the reactor is maintained low by continuously injecting inert gas into the reactor. However, this method also has a big limitation. There is no quantitative control on whether the concentration of inert gas injected into the reactor centrifuge can reach a safe range. There is no clear numerical value as a basis, and it is impossible to deal with various unexpected factors in the feeding. Control, therefore, has poor reliability of protection.

The second is the oxygen content monitoring method:

By installing the reactor oxygen content online analysis system and the centrifuge oxygen content analysis system, the oxygen content in the reactor centrifuge can be monitored online in real time. The principle is to pump a certain amount of gas from the reactor to the analytical instrument through a pipeline to monitor the oxygen content in the reactor centrifuge online in real time, and you can set the concentration alarm value yourself. When the oxygen content reaches the alarm threshold, the analyzer will automatically alarm . Compared with the inert gas replacement method, the online analysis system for online monitoring of the oxygen content in the reactor has very obvious advantages. It fundamentally solves the problem of monitoring the oxygen concentration inside the reactor. However, the shortcomings are also obvious. This is mainly due to different industries and manufacturers. The reactor centrifuge has different feeding materials and different parameters. It needs to be personalized and there is no universal solution. Corresponding pretreatment systems need to be developed for different process parameters.

For example, if the gas in the reactor centrifuge contains corrosive gases, excessive water content, etc., it needs to be pretreated in advance before it can be monitored through the reactor oxygen content online analysis system. At present, this method is mainly adopted by centrifuge manufacturers or terminals are modified by themselves.

Selection of reactor oxygen content online analysis system and centrifuge oxygen content analysis system:

There are usually many methods for detecting oxygen content, such as traditional electrochemistry, ion current, paramagnetic, zirconium oxide, laser and other principles. Generally speaking, special working conditions are treated specially. The gas composition in the centrifuge chamber of the reactor is not complicated. When dealing with corrosive gases, strong acids and alkaline gases, a general electrochemical oxygen analyzer can be considered. The electrochemical principle has good versatility and low price. The disadvantage is that the sensor is not corrosion-resistant and cannot be used directly when there are corrosive or acidic and alkaline gases. It must pass through a pretreatment system before oxygen content analysis can be performed.

When the gas composition in the reactor centrifuge chamber is complex, such as acidic gas (acetic acid), alkaline gas or water vapor, etc., oxygen analyzers using traditional methods such as electrochemistry not only require a complex pretreatment system, but also have poor performance. Relatively poor, a magnetic oxygen analyzer or laser oxygen analyzer is generally recommended under such working conditions.

Because the paramagnetic oxygen analyzer uses physical principles (note: electrochemistry is a chemical principle) to measure oxygen content, it only needs simple preprocessing. It can be installed in direct pipelines and can accept acidic gases and alkaline gases. The influence of water vapor and water vapor is small, and the oxygen content is directly monitored.

In addition to electrochemical oxygen analyzers and magnetic oxygen analyzers, there are also laser oxygen analysis systems. Like magnetic oxygen, laser oxygen uses optical principles to measure oxygen content and is not sensitive to acidic, alkaline, corrosive and other gases. The only real disadvantage is that it has requirements for the content of dust and other particulate matter in the measured gas.

ㅤ

ㅤ