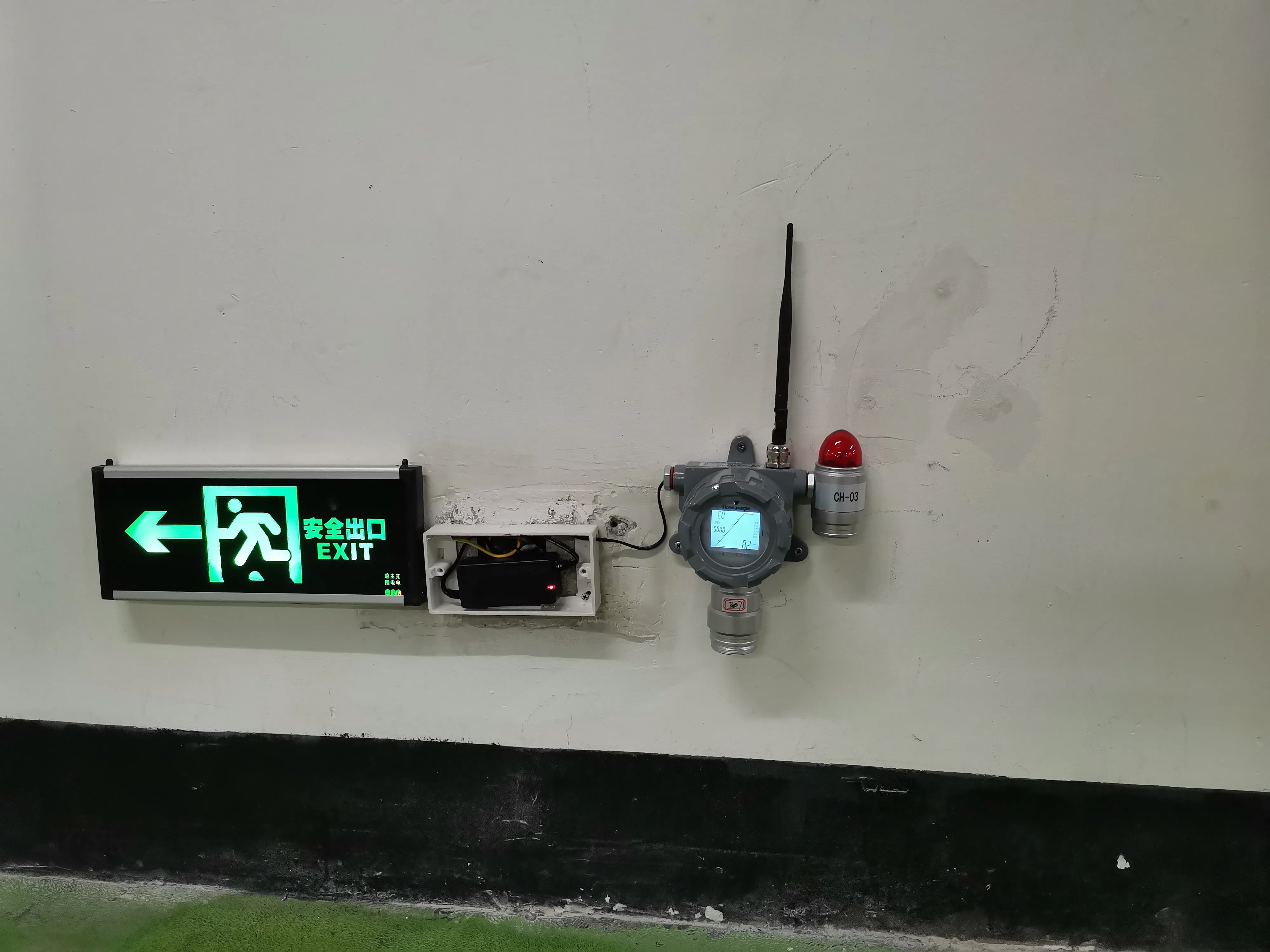

Case studies of indoor fixed gas detectors

Release time:2025-10-15

Source:ㅤ

This fixed gas detector is specifically designed for continuous monitoring of specific hazardous gases in indoor environments, including sulfur dioxide, oxygen, carbon monoxide and hydrogen sulfide. The equipment is fixedly installed to achieve all-weather monitoring of gas concentration in the target area.

The core measurement function of the instrument is based on high-speed and high-precision processing circuits and combined with full-range temperature digital compensation technology. This technology combination aims to reduce the impact of environmental temperature changes on measurement results, thereby achieving rapid and accurate measurement of gas concentration under different working conditions and reducing data errors.

In terms of signal output, the device simultaneously offers two standard industrial interfaces: a 4-20mA three-wire analog signal and an RS485 digital signal. These interfaces enable it to be connected to data acquisition modules, PLCS or computer systems to complete the real-time transmission of measurement data.

Through the upper computer software or monitoring system, the transmitted data can be centrally displayed and recorded, forming a visual concentration change trend chart. This enables staff to keep track of the status changes of key gases indoors in real time, providing a basis for environmental safety assessment and timely response.

The application of this device provides a stable and continuous monitoring solution for indoor places that need to continuously monitor gas leakage, oxygen deficiency or accumulation of harmful gases.

|

|

|

|

|

|

|

|

|

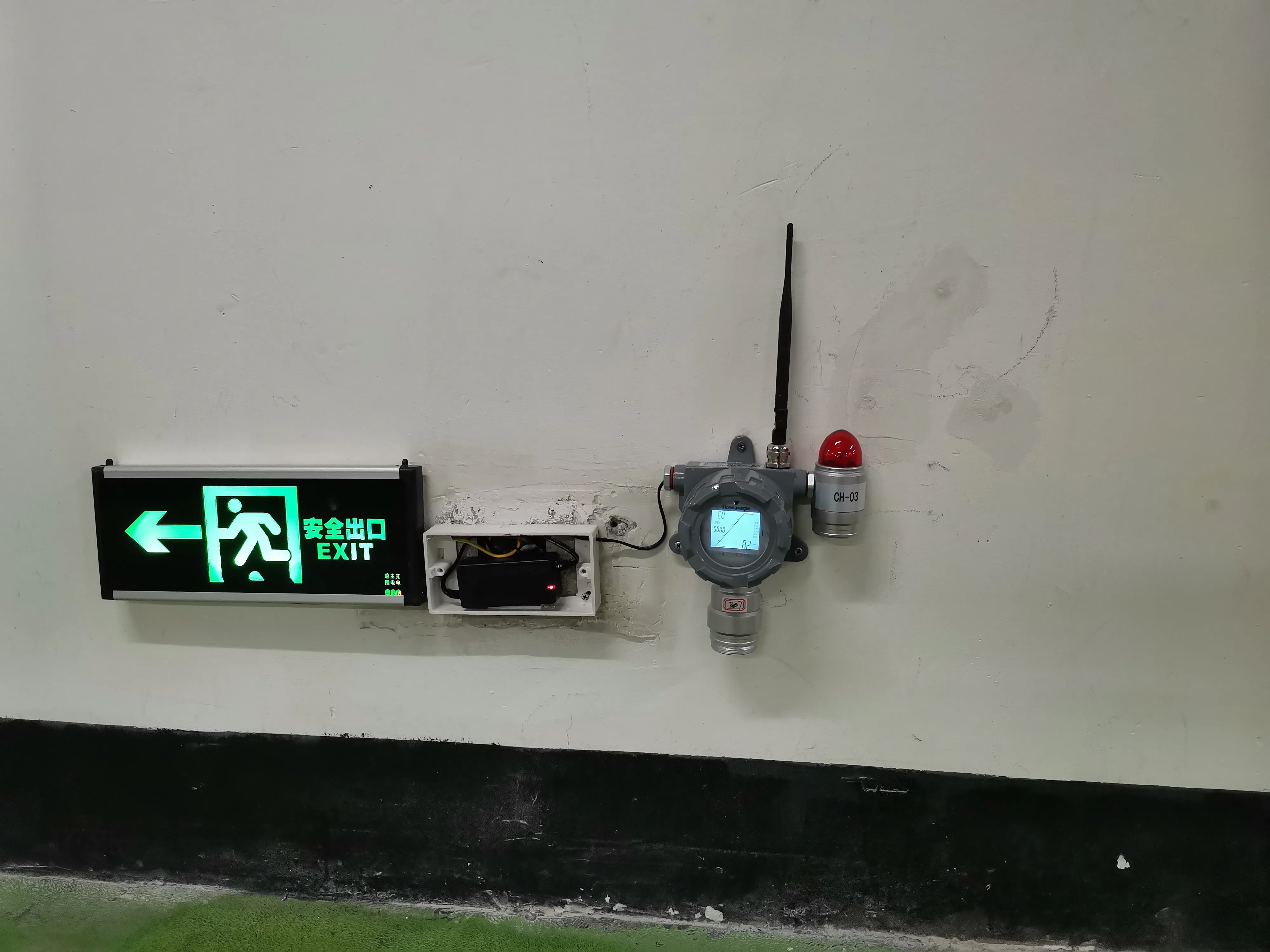

This fixed gas detector is specifically designed for continuous monitoring of specific hazardous gases in indoor environments, including sulfur dioxide, oxygen, carbon monoxide and hydrogen sulfide. The equipment is fixedly installed to achieve all-weather monitoring of gas concentration in the target area.

The core measurement function of the instrument is based on high-speed and high-precision processing circuits and combined with full-range temperature digital compensation technology. This technology combination aims to reduce the impact of environmental temperature changes on measurement results, thereby achieving rapid and accurate measurement of gas concentration under different working conditions and reducing data errors.

In terms of signal output, the device simultaneously offers two standard industrial interfaces: a 4-20mA three-wire analog signal and an RS485 digital signal. These interfaces enable it to be connected to data acquisition modules, PLCS or computer systems to complete the real-time transmission of measurement data.

Through the upper computer software or monitoring system, the transmitted data can be centrally displayed and recorded, forming a visual concentration change trend chart. This enables staff to keep track of the status changes of key gases indoors in real time, providing a basis for environmental safety assessment and timely response.

The application of this device provides a stable and continuous monitoring solution for indoor places that need to continuously monitor gas leakage, oxygen deficiency or accumulation of harmful gases.

|

|

|

|

|

|

|

|

|

ㅤ

ㅤ