Application Case of Online Gas Pretreatment Monitoring System for Waste Treatment Plants

Release time:2025-10-29

Source:ㅤ

I. Project Background

A large-scale waste treatment plant is mainly responsible for the centralized treatment of municipal solid waste, industrial solid waste and other types of waste. During the fermentation and degradation of the waste, the pipelines in the treatment workshop will produce a mixed gas containing various characteristic gases such as H₂S, VOC, CO and CO₂. Due to the fact that a large amount of water evaporates during the waste disposal process, the pipeline is constantly in a high-humidity environment. Moreover, to ensure the efficiency of gas collection, a negative pressure state is maintained inside the pipeline. As a result, ordinary gas monitoring equipment often experiences sensor moisture failure and data drift due to the high-humidity environment, making it impossible to accurately capture changes in gas concentration. This poses a significant threat to the safe operation and environmental protection compliance of the factory area. To address this issue, the factory has introduced an online gas pretreatment monitoring system to achieve real-time and precise monitoring of the target gas within the pipeline.

Ii. System Deployment Plan

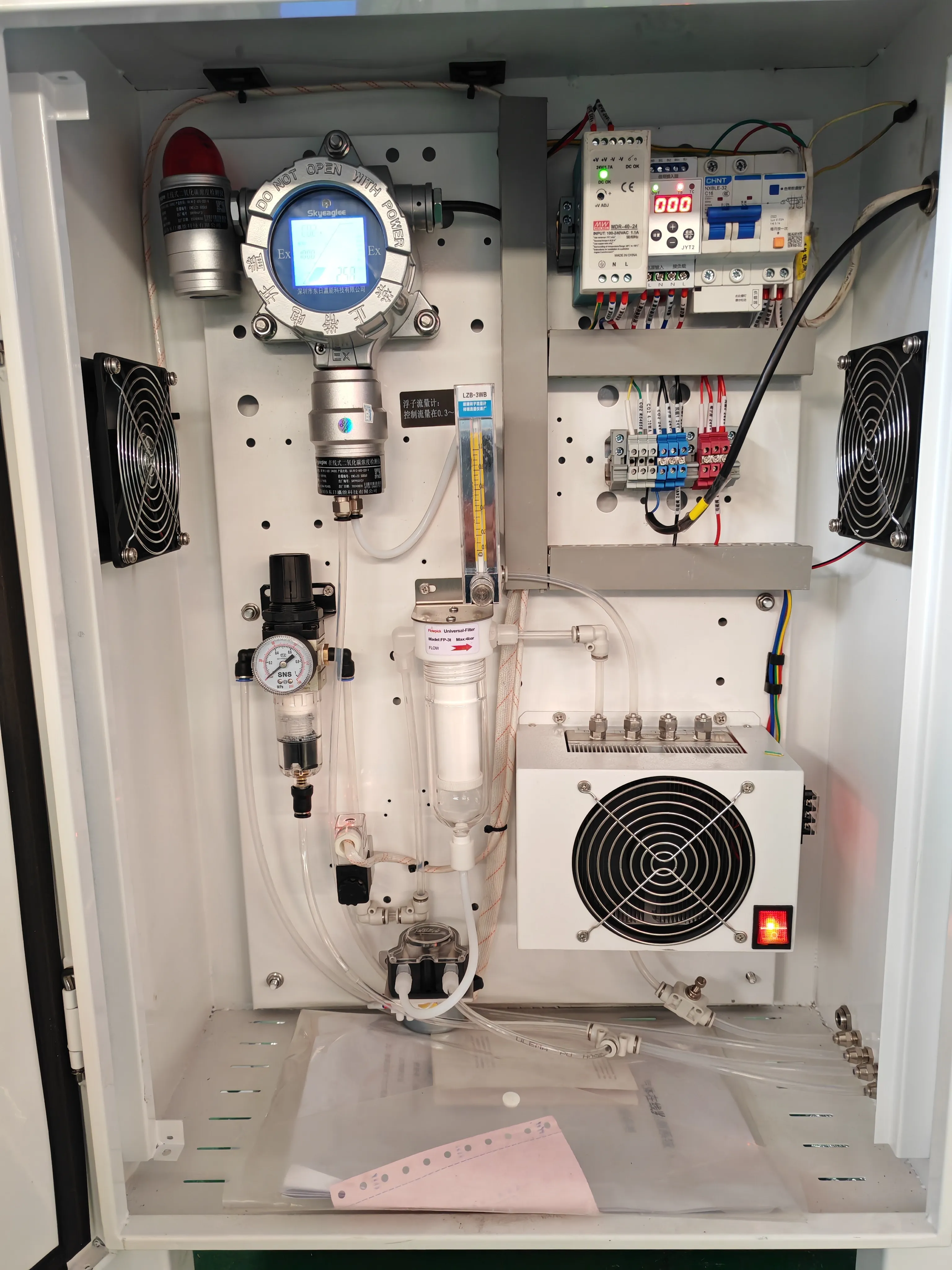

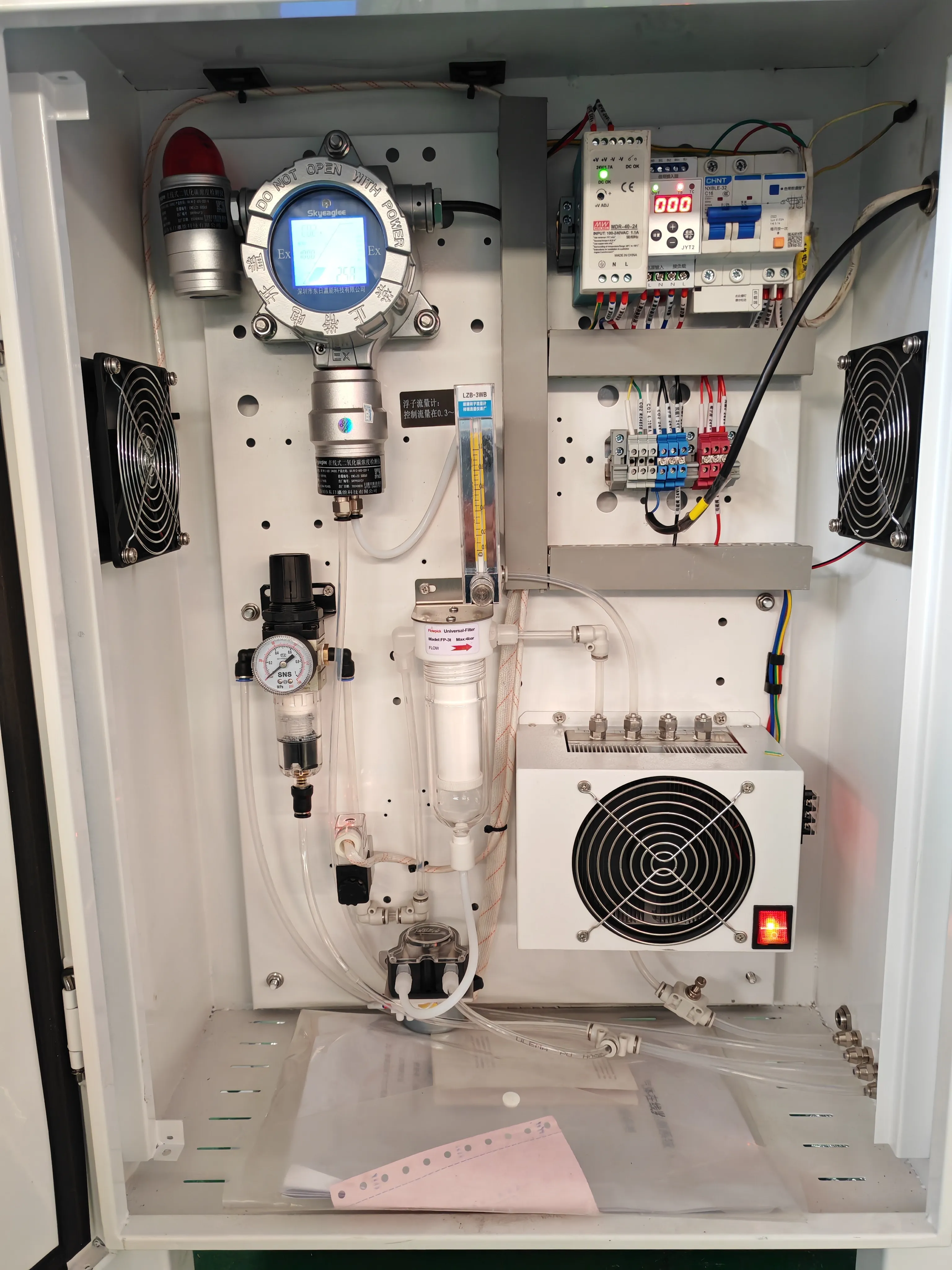

In response to the high humidity, negative pressure and non-corrosive gas monitoring environment of the factory's pipelines, the online gas pretreatment monitoring system deployed this time is built around the three core requirements of "precise dehumidification, stable sampling and visible data". All components work in coordination. The specific configuration and functions are as follows:

1. Sampling and transmission module: PTFE tubes are used as gas transmission pipelines, which have excellent weather resistance and sealing performance. They can stably convey gas in a negative pressure environment, avoiding gas leakage that may affect monitoring accuracy. Connect the pipeline to the system with a dedicated connector to ensure the sealing of the sampling interface and prevent interference from external air. Meanwhile, the system is equipped with a high-performance air pump. Through a negative pressure adaptation design, it can stably extract gas samples from the pipeline, ensuring the uniformity of the sampling flow.

2. Pretreatment module: This is the core link in dealing with high-humidity environments. The system is equipped with an electronic condenser, which precisely controls the temperature to condense the moisture in the gas into liquid water, effectively reducing the gas humidity. To promptly discharge condensate water, the system is equipped with a time relay, which can preset the drainage cycle based on the on-site humidity conditions and automatically control the peristaltic pump to start drainage, avoiding the accumulation of condensate water that affects gas transmission and sensor performance. In addition, a filter is installed at the sampling end, which can filter out dust, particles and other impurities in the gas to prevent pipeline blockage and damage to subsequent equipment.

3. Monitoring and Display Module: The system integrates dedicated sensors for H₂S, VOC, CO, and CO₂, enabling real-time collection of gas concentration data. Equipped with a 7-inch LCD touch screen, it can not only clearly display real-time data such as the concentration, humidity and flow rate of various gases, but also support functions such as historical data query and alarm threshold setting. It is easy to operate and enables on-site staff to grasp the gas conditions in the pipeline in real time.

4. Power Supply module: It adopts a stable industrial-grade power supply to ensure the continuous operation of the system in the complex power supply environment of the factory area and avoid monitoring interruption caused by unstable power supply.

Iii. System Operation Effect

After the system was deployed and put into operation, it effectively solved the problem of gas monitoring in the high-humidity negative pressure pipeline of the factory. The specific effects are as follows:

Remarkable dehumidification effect The electronic condenser, in conjunction with the time relay and peristaltic pump, keeps the humidity of the gas inside the pipeline stably within the range suitable for the sensor's operation, avoiding problems such as sensor data drift and failure caused by high humidity. The monitoring data accuracy of H₂S, VOC, CO, and CO₂ has been significantly improved, and the data fluctuation range is controlled within the error range allowed by industry standards.

Stable and reliable operation: The filter effectively filters impurities, and there is no blockage in the pipeline. The industrial-grade power supply guarantee system operates continuously for 24 hours without any monitoring interruption. The time relay precisely controls the drainage, eliminating the need for frequent manual intervention and reducing operation and maintenance costs.

Data visualization is convenient: The 7-inch touch screen clearly displays all data. Staff can view the real-time trend of gas concentration changes. When the concentration of a certain gas approaches the alarm threshold, the system will automatically issue an audible and visual alarm, providing timely early warning support for the safe operation and environmental protection emissions of the factory area. Up to now, the system has been operating stably for six months, helping the factory pass multiple on-site inspections by environmental protection departments smoothly. No environmental protection issues caused by abnormal gas monitoring data have occurred.

Iv. Project Summary

In this case, the online gas pretreatment monitoring system, through targeted component configurations (such as electronic condensers, time relays, PTFE tubes, etc.), perfectly adapted to the high-humidity and negative pressure pipeline monitoring environment of the waste treatment plant, achieving precise and stable monitoring of four gases: H₂S, VOC, CO, and CO₂. Not only does it solve the pain points of traditional monitoring equipment in complex environments, but it also provides reliable technical support for the safety management and environmental protection compliance of the factory area. It is a typical application example of gas monitoring in high-humidity environments in the waste treatment industry.

I. Project Background

A large-scale waste treatment plant is mainly responsible for the centralized treatment of municipal solid waste, industrial solid waste and other types of waste. During the fermentation and degradation of the waste, the pipelines in the treatment workshop will produce a mixed gas containing various characteristic gases such as H₂S, VOC, CO and CO₂. Due to the fact that a large amount of water evaporates during the waste disposal process, the pipeline is constantly in a high-humidity environment. Moreover, to ensure the efficiency of gas collection, a negative pressure state is maintained inside the pipeline. As a result, ordinary gas monitoring equipment often experiences sensor moisture failure and data drift due to the high-humidity environment, making it impossible to accurately capture changes in gas concentration. This poses a significant threat to the safe operation and environmental protection compliance of the factory area. To address this issue, the factory has introduced an online gas pretreatment monitoring system to achieve real-time and precise monitoring of the target gas within the pipeline.

Ii. System Deployment Plan

In response to the high humidity, negative pressure and non-corrosive gas monitoring environment of the factory's pipelines, the online gas pretreatment monitoring system deployed this time is built around the three core requirements of "precise dehumidification, stable sampling and visible data". All components work in coordination. The specific configuration and functions are as follows:

1. Sampling and transmission module: PTFE tubes are used as gas transmission pipelines, which have excellent weather resistance and sealing performance. They can stably convey gas in a negative pressure environment, avoiding gas leakage that may affect monitoring accuracy. Connect the pipeline to the system with a dedicated connector to ensure the sealing of the sampling interface and prevent interference from external air. Meanwhile, the system is equipped with a high-performance air pump. Through a negative pressure adaptation design, it can stably extract gas samples from the pipeline, ensuring the uniformity of the sampling flow.

2. Pretreatment module: This is the core link in dealing with high-humidity environments. The system is equipped with an electronic condenser, which precisely controls the temperature to condense the moisture in the gas into liquid water, effectively reducing the gas humidity. To promptly discharge condensate water, the system is equipped with a time relay, which can preset the drainage cycle based on the on-site humidity conditions and automatically control the peristaltic pump to start drainage, avoiding the accumulation of condensate water that affects gas transmission and sensor performance. In addition, a filter is installed at the sampling end, which can filter out dust, particles and other impurities in the gas to prevent pipeline blockage and damage to subsequent equipment.

3. Monitoring and Display Module: The system integrates dedicated sensors for H₂S, VOC, CO, and CO₂, enabling real-time collection of gas concentration data. Equipped with a 7-inch LCD touch screen, it can not only clearly display real-time data such as the concentration, humidity and flow rate of various gases, but also support functions such as historical data query and alarm threshold setting. It is easy to operate and enables on-site staff to grasp the gas conditions in the pipeline in real time.

4. Power Supply module: It adopts a stable industrial-grade power supply to ensure the continuous operation of the system in the complex power supply environment of the factory area and avoid monitoring interruption caused by unstable power supply.

Iii. System Operation Effect

After the system was deployed and put into operation, it effectively solved the problem of gas monitoring in the high-humidity negative pressure pipeline of the factory. The specific effects are as follows:

Remarkable dehumidification effect The electronic condenser, in conjunction with the time relay and peristaltic pump, keeps the humidity of the gas inside the pipeline stably within the range suitable for the sensor's operation, avoiding problems such as sensor data drift and failure caused by high humidity. The monitoring data accuracy of H₂S, VOC, CO, and CO₂ has been significantly improved, and the data fluctuation range is controlled within the error range allowed by industry standards.

Stable and reliable operation: The filter effectively filters impurities, and there is no blockage in the pipeline. The industrial-grade power supply guarantee system operates continuously for 24 hours without any monitoring interruption. The time relay precisely controls the drainage, eliminating the need for frequent manual intervention and reducing operation and maintenance costs.

Data visualization is convenient: The 7-inch touch screen clearly displays all data. Staff can view the real-time trend of gas concentration changes. When the concentration of a certain gas approaches the alarm threshold, the system will automatically issue an audible and visual alarm, providing timely early warning support for the safe operation and environmental protection emissions of the factory area. Up to now, the system has been operating stably for six months, helping the factory pass multiple on-site inspections by environmental protection departments smoothly. No environmental protection issues caused by abnormal gas monitoring data have occurred.

Iv. Project Summary

In this case, the online gas pretreatment monitoring system, through targeted component configurations (such as electronic condensers, time relays, PTFE tubes, etc.), perfectly adapted to the high-humidity and negative pressure pipeline monitoring environment of the waste treatment plant, achieving precise and stable monitoring of four gases: H₂S, VOC, CO, and CO₂. Not only does it solve the pain points of traditional monitoring equipment in complex environments, but it also provides reliable technical support for the safety management and environmental protection compliance of the factory area. It is a typical application example of gas monitoring in high-humidity environments in the waste treatment industry.

ㅤ

ㅤ