Solutions for combustible and toxic gases in confined space

Release time:2024-04-18

Source:ㅤ

Principles for working in a confined space: ventilate first, then inspect, and then operate

Definition of confined space: It refers to a space with restricted entrances and exits but sufficient to accommodate personnel to enter and perform operations, or with limited natural ventilation and a small space that is not suitable for workers to stay continuously. Such as entering or exploring towers, tanks, tankers, pipes, furnaces, flues, tunnels, sewers, trenches, pits, wells, pools, culverts and other closed and semi-closed equipment and places where toxic gases and combustible gases may accumulate.

Unconventional limited space (or special limited space): refers to a limited space where the working environment does not meet or comply with relevant national and industry regulations and can cause personal injuries such as poisoning, suffocation, electric shock, explosion, etc. to workers.

In order to prevent workers from poisoning, suffocation, explosion and other risks in the environment, the following product can be customized according to customer requirements.

Limited space operation equipment requires explosion-proof situations, and the entire equipment is explosion-proof. There are four conventional gas detection equipment on the market. This instrument can detect 9 gases at the same time. The four common gases in limited working spaces are methane, oxygen, carbon monoxide, and hydrogen sulfide. Some requirements also require the detection of carbon dioxide, ammonia and other gases.

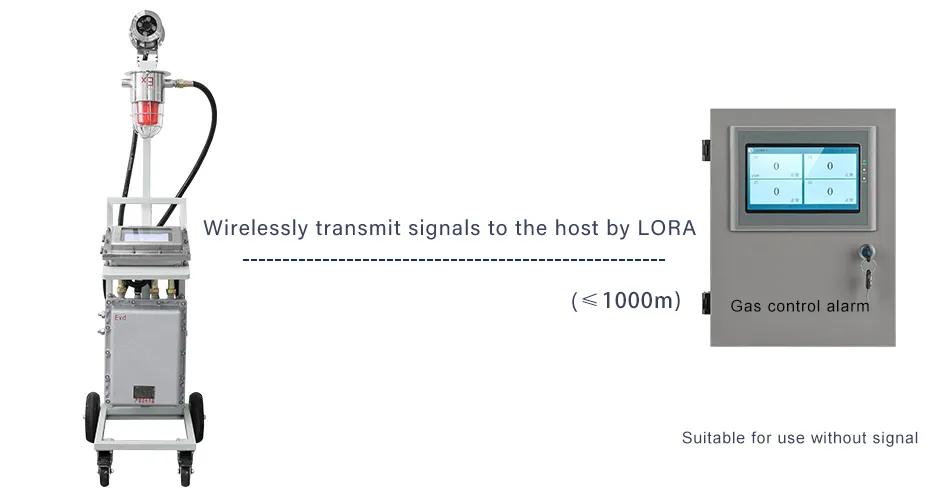

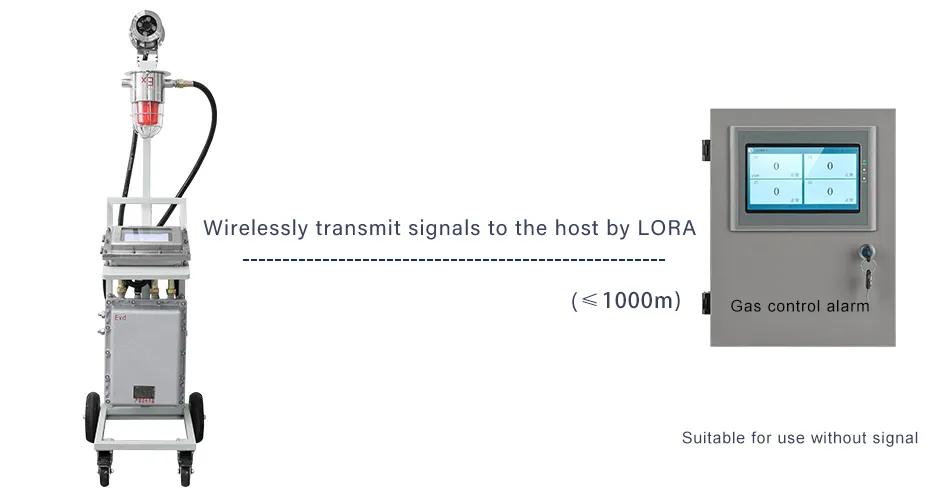

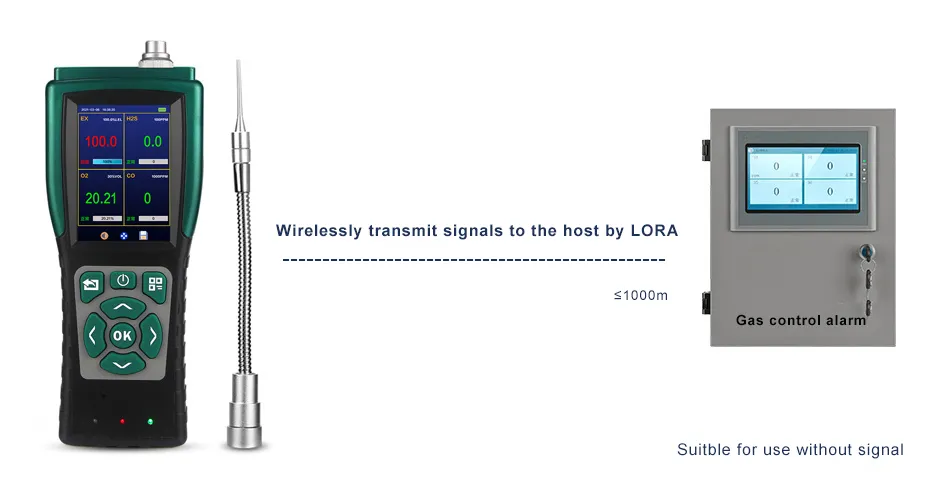

The mobile gas detection and monitoring system can communicate with the host through LORA (optional)

When workers use the mobile gas detection system for detection during work, once the gas exceeds the standard and is dangerous, the data can be transmitted to the host and an alarm will be issued to prevent the host from alarming and reminding people when they do not often look at the data.

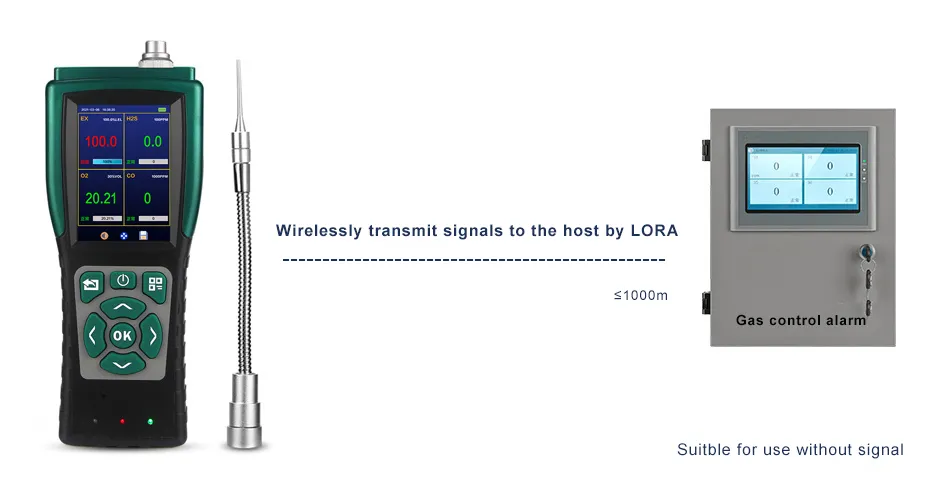

The handheld gas detector can also transmit occupancy data through LORA. During underground construction, if the concentration exceeds the standard, the data can be sent to the host for alarm.

Mobile gas detection and monitoring system

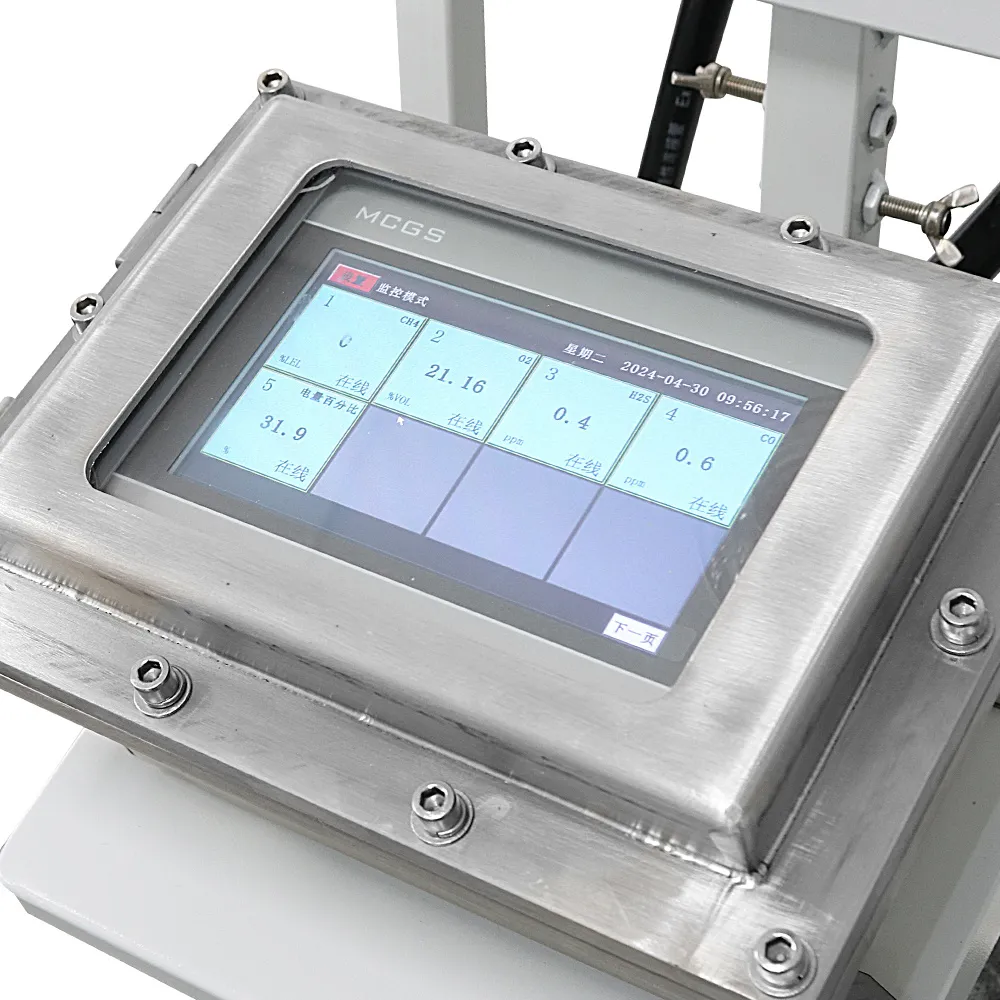

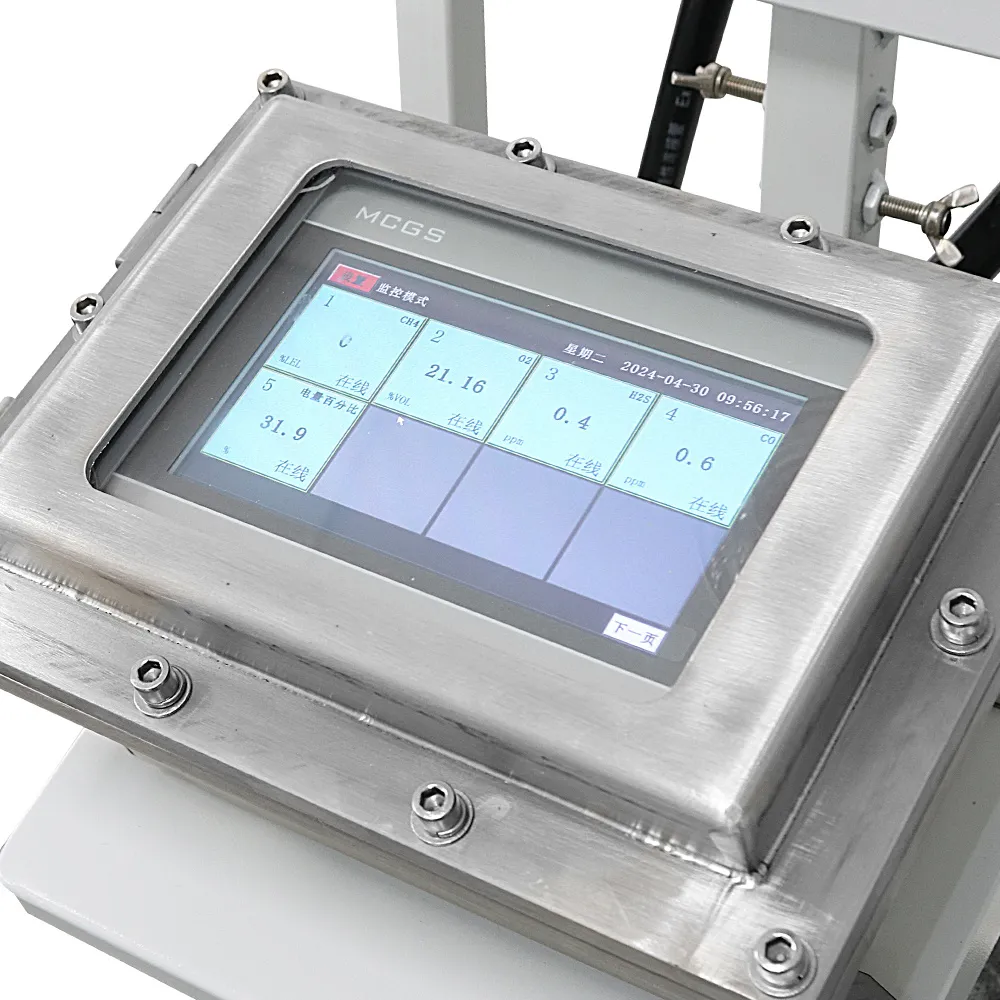

The mobile gas detection and monitoring system can continuously monitor online for about 78 hours. The maximum sampling distance of the built-in air pump is about 100 meters. The seven-inch LCD touch screen allows you to operate gas zeroing, calibration, low alarm, high alarm, address, reset and other functions through the screen. You can query 1,000 alarm records and 100,000 historical data on this machine. (Storage interval can be set for historical data)

The built-in 4G module can upload data to the cloud platform, and can query the current concentration and historical data of the equipment through a mobile phone or computer. When the gas concentration exceeds the standard, a text message or a call can be sent to the mobile phone for notification, ensuring that on-site work can be grasped as soon as possible. conditions to avoid poisoning of personnel at construction sites.

The equipment is also equipped with a surveillance camera, which can monitor the on-site environment at the same time, and the current concentration of monitoring and gas can be viewed simultaneously on the cloud platform.

Conventional four gas equipment ranges:

CH4:0-100%LEL Low alarm value: 25%LEL (the alarm value is set according to the actual situation on site)

O2: 0-30%VOL, low alarm value 19.5%VOL, high alarm value 23.5%VOL

CO: 0-1200PPM Low alarm value: 200PPM (the alarm value is set according to the actual situation on site)

H2S: 0-100PPM, low alarm value 20PPM (the alarm value is set according to the actual situation on site)

CO2: 0-5000PPM, low alarm value 1500PPM (the alarm value is set according to the actual situation on site)

(A variety of gases can be customized) Detection principle: catalytic combustion, electrochemistry (Infrared/PID/thermal conductivity and other principles can be customized)

Implementation standards:

GB3836.1-2010 "Electrical equipment for explosive gas environments Part 1: General requirements"

GB3836.2-2010 "Electrical equipment for explosive gas environments Part 2: Flameproof type "d" "

GB 3836.15-2000 "Electrical equipment for explosive gas environments Part 15: Electrical installation in hazardous locations (except coal mines)"

GBT50493-2019 Petrochemical odor and toxic gas detection and alarm design standards

GB12358-2006 "General technical requirements for ambient gas detection and alarm devices in workplaces"

GBZ 2.1-2007 "Occupational Exposure Limits for Hazardous Factors in the Workplace"

Sampling accuracy: ±3%F.S

Response time: T90<10S

Working temperature: -20 ~ 50℃

Sampling environment temperature: below 80 degrees Celsius (no condensation and small water droplets)

RS485 signal: using standard MODBUS RTU protocol, transmission distance 1Km

According to the on-site working conditions, when the on-site environment has no signal, it can also be customized for LORA signal transmission, and the host can be configured to send data to points, and then the data can be transmitted to the cloud platform through the host.

Principles for working in a confined space: ventilate first, then inspect, and then operate

Definition of confined space: It refers to a space with restricted entrances and exits but sufficient to accommodate personnel to enter and perform operations, or with limited natural ventilation and a small space that is not suitable for workers to stay continuously. Such as entering or exploring towers, tanks, tankers, pipes, furnaces, flues, tunnels, sewers, trenches, pits, wells, pools, culverts and other closed and semi-closed equipment and places where toxic gases and combustible gases may accumulate.

Unconventional limited space (or special limited space): refers to a limited space where the working environment does not meet or comply with relevant national and industry regulations and can cause personal injuries such as poisoning, suffocation, electric shock, explosion, etc. to workers.

In order to prevent workers from poisoning, suffocation, explosion and other risks in the environment, the following product can be customized according to customer requirements.

Limited space operation equipment requires explosion-proof situations, and the entire equipment is explosion-proof. There are four conventional gas detection equipment on the market. This instrument can detect 9 gases at the same time. The four common gases in limited working spaces are methane, oxygen, carbon monoxide, and hydrogen sulfide. Some requirements also require the detection of carbon dioxide, ammonia and other gases.

The mobile gas detection and monitoring system can communicate with the host through LORA (optional)

When workers use the mobile gas detection system for detection during work, once the gas exceeds the standard and is dangerous, the data can be transmitted to the host and an alarm will be issued to prevent the host from alarming and reminding people when they do not often look at the data.

The handheld gas detector can also transmit occupancy data through LORA. During underground construction, if the concentration exceeds the standard, the data can be sent to the host for alarm.

Mobile gas detection and monitoring system

The mobile gas detection and monitoring system can continuously monitor online for about 78 hours. The maximum sampling distance of the built-in air pump is about 100 meters. The seven-inch LCD touch screen allows you to operate gas zeroing, calibration, low alarm, high alarm, address, reset and other functions through the screen. You can query 1,000 alarm records and 100,000 historical data on this machine. (Storage interval can be set for historical data)

The built-in 4G module can upload data to the cloud platform, and can query the current concentration and historical data of the equipment through a mobile phone or computer. When the gas concentration exceeds the standard, a text message or a call can be sent to the mobile phone for notification, ensuring that on-site work can be grasped as soon as possible. conditions to avoid poisoning of personnel at construction sites.

The equipment is also equipped with a surveillance camera, which can monitor the on-site environment at the same time, and the current concentration of monitoring and gas can be viewed simultaneously on the cloud platform.

Conventional four gas equipment ranges:

CH4:0-100%LEL Low alarm value: 25%LEL (the alarm value is set according to the actual situation on site)

O2: 0-30%VOL, low alarm value 19.5%VOL, high alarm value 23.5%VOL

CO: 0-1200PPM Low alarm value: 200PPM (the alarm value is set according to the actual situation on site)

H2S: 0-100PPM, low alarm value 20PPM (the alarm value is set according to the actual situation on site)

CO2: 0-5000PPM, low alarm value 1500PPM (the alarm value is set according to the actual situation on site)

(A variety of gases can be customized) Detection principle: catalytic combustion, electrochemistry (Infrared/PID/thermal conductivity and other principles can be customized)

Implementation standards:

GB3836.1-2010 "Electrical equipment for explosive gas environments Part 1: General requirements"

GB3836.2-2010 "Electrical equipment for explosive gas environments Part 2: Flameproof type "d" "

GB 3836.15-2000 "Electrical equipment for explosive gas environments Part 15: Electrical installation in hazardous locations (except coal mines)"

GBT50493-2019 Petrochemical odor and toxic gas detection and alarm design standards

GB12358-2006 "General technical requirements for ambient gas detection and alarm devices in workplaces"

GBZ 2.1-2007 "Occupational Exposure Limits for Hazardous Factors in the Workplace"

Sampling accuracy: ±3%F.S

Response time: T90<10S

Working temperature: -20 ~ 50℃

Sampling environment temperature: below 80 degrees Celsius (no condensation and small water droplets)

RS485 signal: using standard MODBUS RTU protocol, transmission distance 1Km

According to the on-site working conditions, when the on-site environment has no signal, it can also be customized for LORA signal transmission, and the host can be configured to send data to points, and then the data can be transmitted to the cloud platform through the host.

ㅤ

ㅤ