Online Monitoring of Exhaust Gases in Industrial Production Pipelines

Release time:2025-12-03

Source:Skyeaglee case

Application Scenario: Industrial production pipeline exhaust / process gas detection scenarios

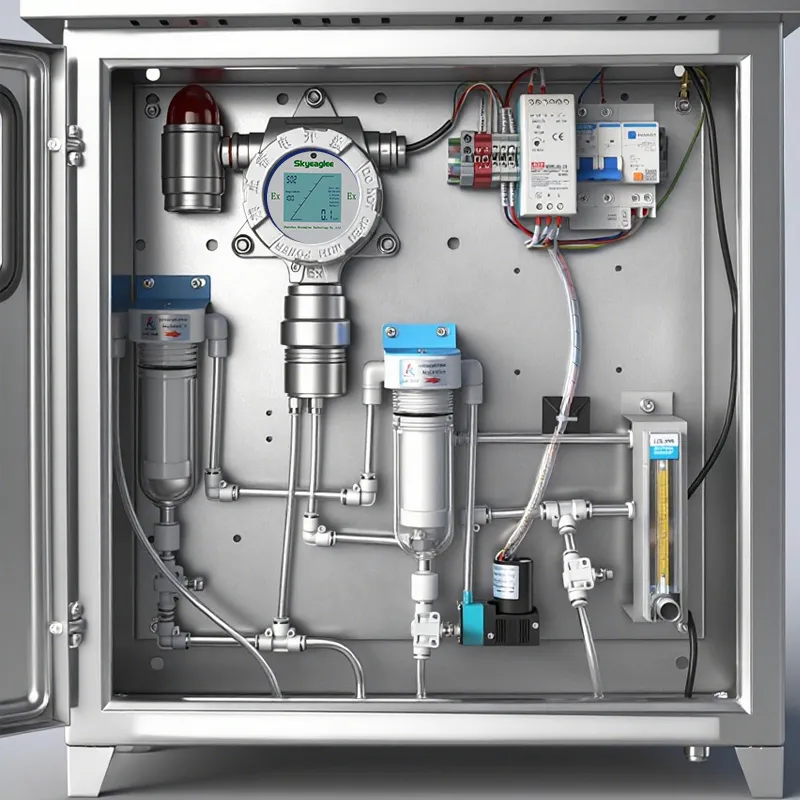

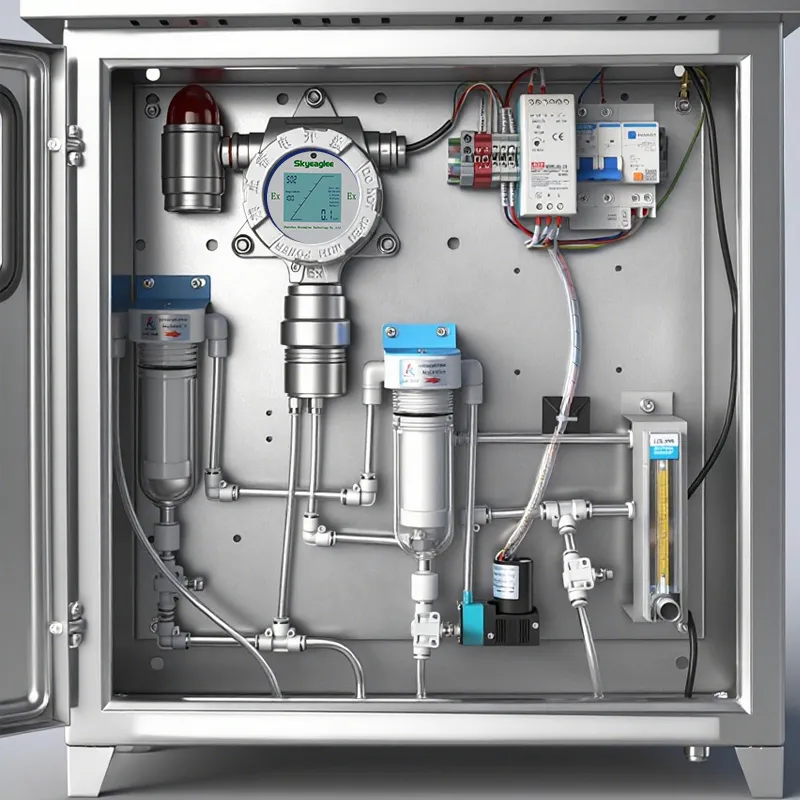

Products Used: Online gas pretreatment system + Fixed gas detector

Gases Measured: CO (Carbon Monoxide), NO (Nitric Oxide), O₂ (Oxygen), EX (Combustible Gas)

Measuring Ranges:

NO₂: 0–1000 ppm

NO: 0–250 ppm

O₂: 0–30% VOL

EX: 0–100% LEL

(Note: Specific ranges can be customized according to actual working conditions.)

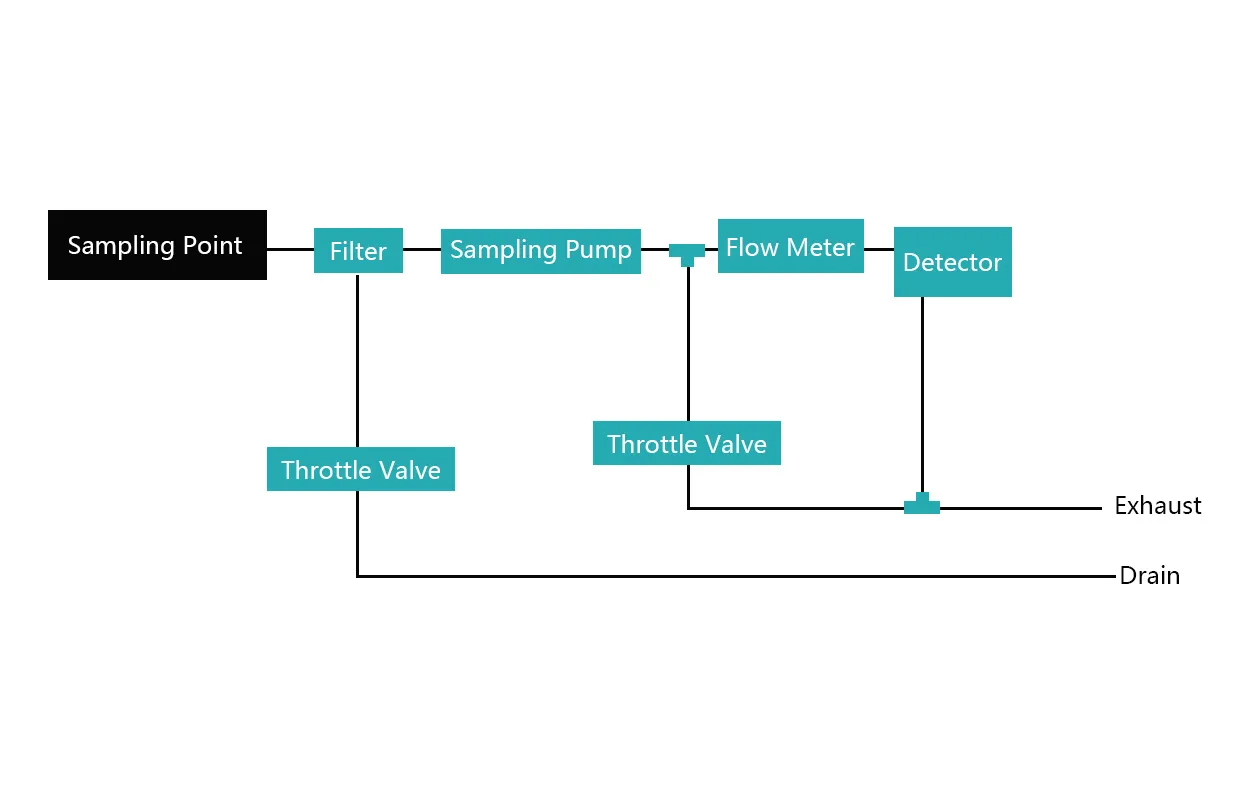

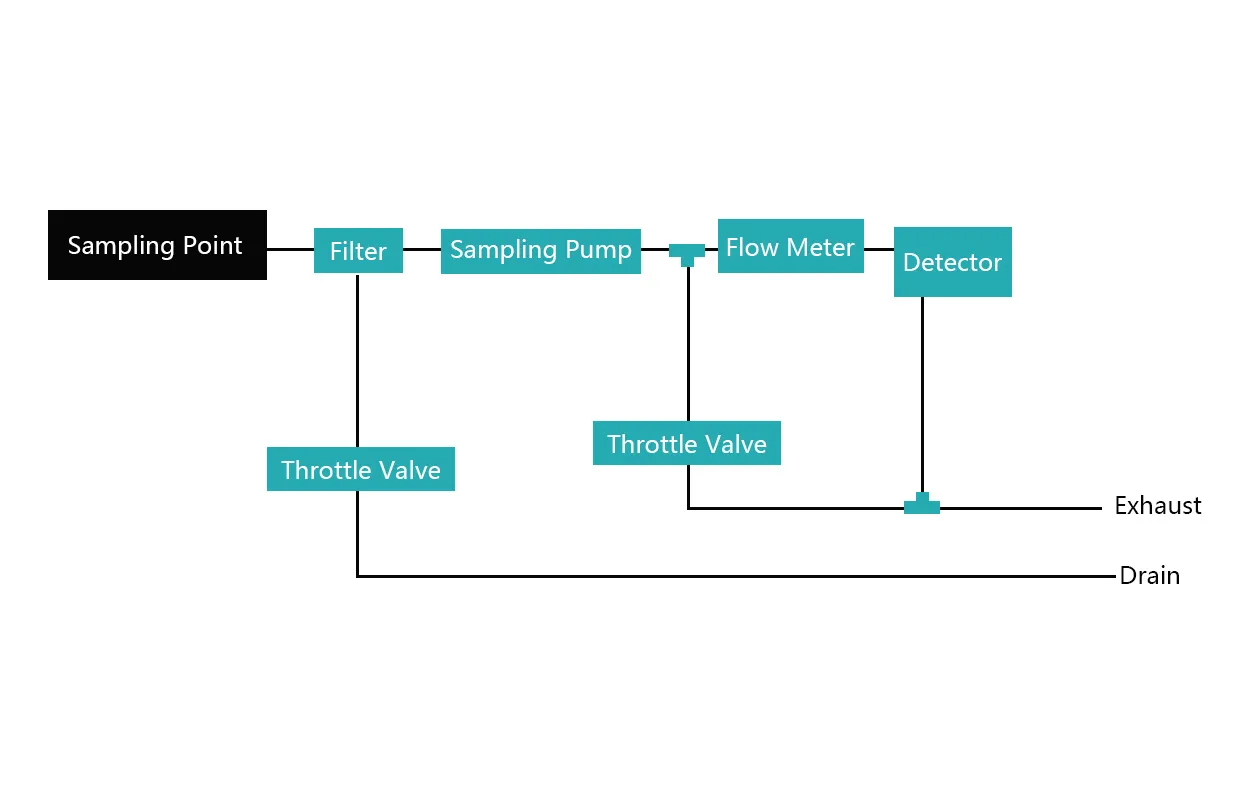

Main Functions: The sampled gas first passes through a filter to remove dust and impurities, then is drawn by a sampling pump to a flowmeter to control the gas flow rate (flowmeter rate is generally set at 0.3–0.5 L/min). Finally, the gas reaches the instrument for detection (the instrument’s operating environment must be within -20°C to 60°C). Water accumulated in the filter needs to be manually drained.

|

|

Application Scenario: Industrial production pipeline exhaust / process gas detection scenarios

Products Used: Online gas pretreatment system + Fixed gas detector

Gases Measured: CO (Carbon Monoxide), NO (Nitric Oxide), O₂ (Oxygen), EX (Combustible Gas)

Measuring Ranges:

NO₂: 0–1000 ppm

NO: 0–250 ppm

O₂: 0–30% VOL

EX: 0–100% LEL

(Note: Specific ranges can be customized according to actual working conditions.)

Main Functions: The sampled gas first passes through a filter to remove dust and impurities, then is drawn by a sampling pump to a flowmeter to control the gas flow rate (flowmeter rate is generally set at 0.3–0.5 L/min). Finally, the gas reaches the instrument for detection (the instrument’s operating environment must be within -20°C to 60°C). Water accumulated in the filter needs to be manually drained.

|

|

|

|