Case of Online Monitoring of Carbon Monoxide in Kilns of Building Materials Enterprises: Upgrading Safety Production from Numerous Hidden Dangers to Intelligent Control

Release time:2025-11-05

Source:A real case of skyeaglee

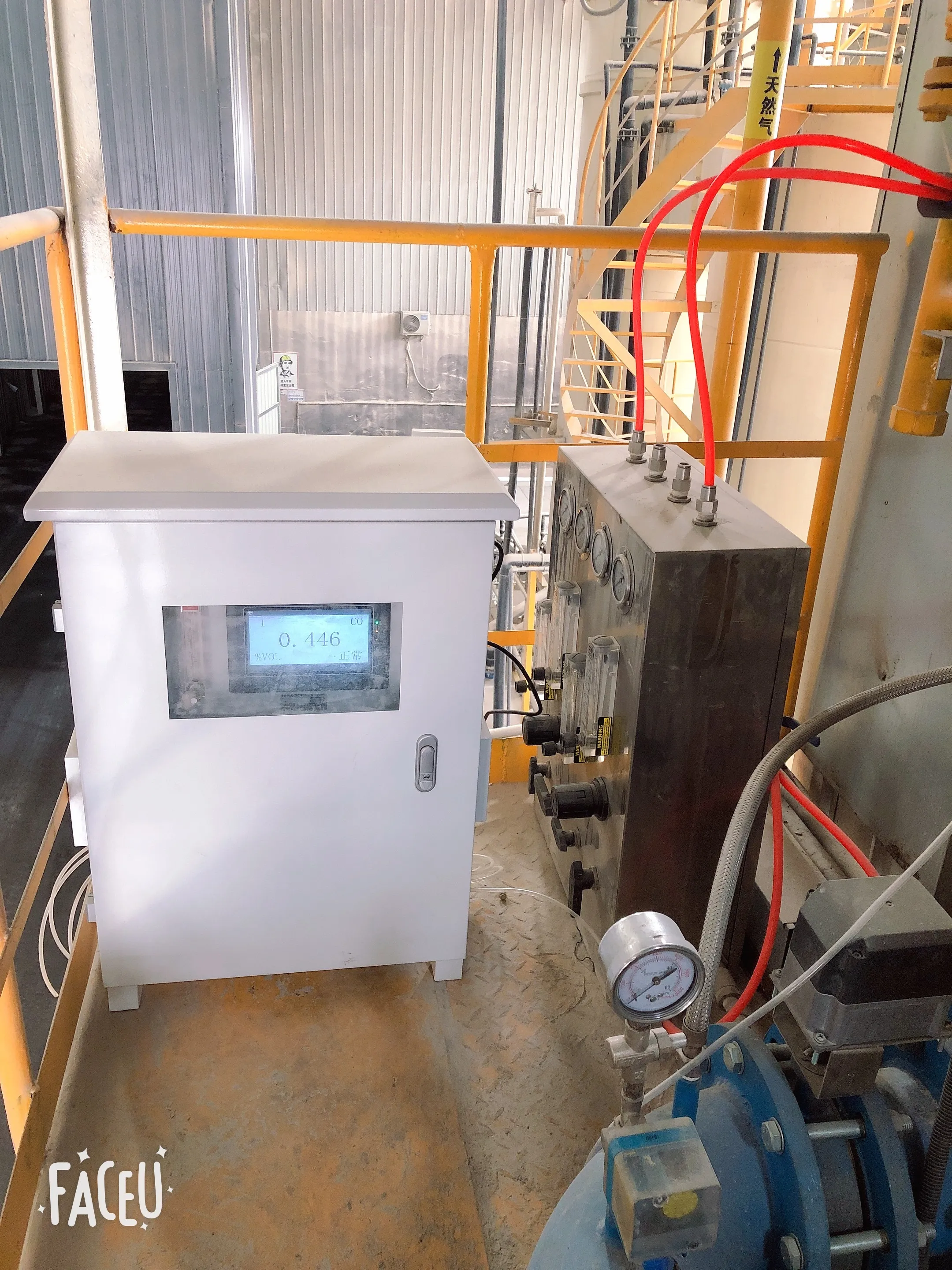

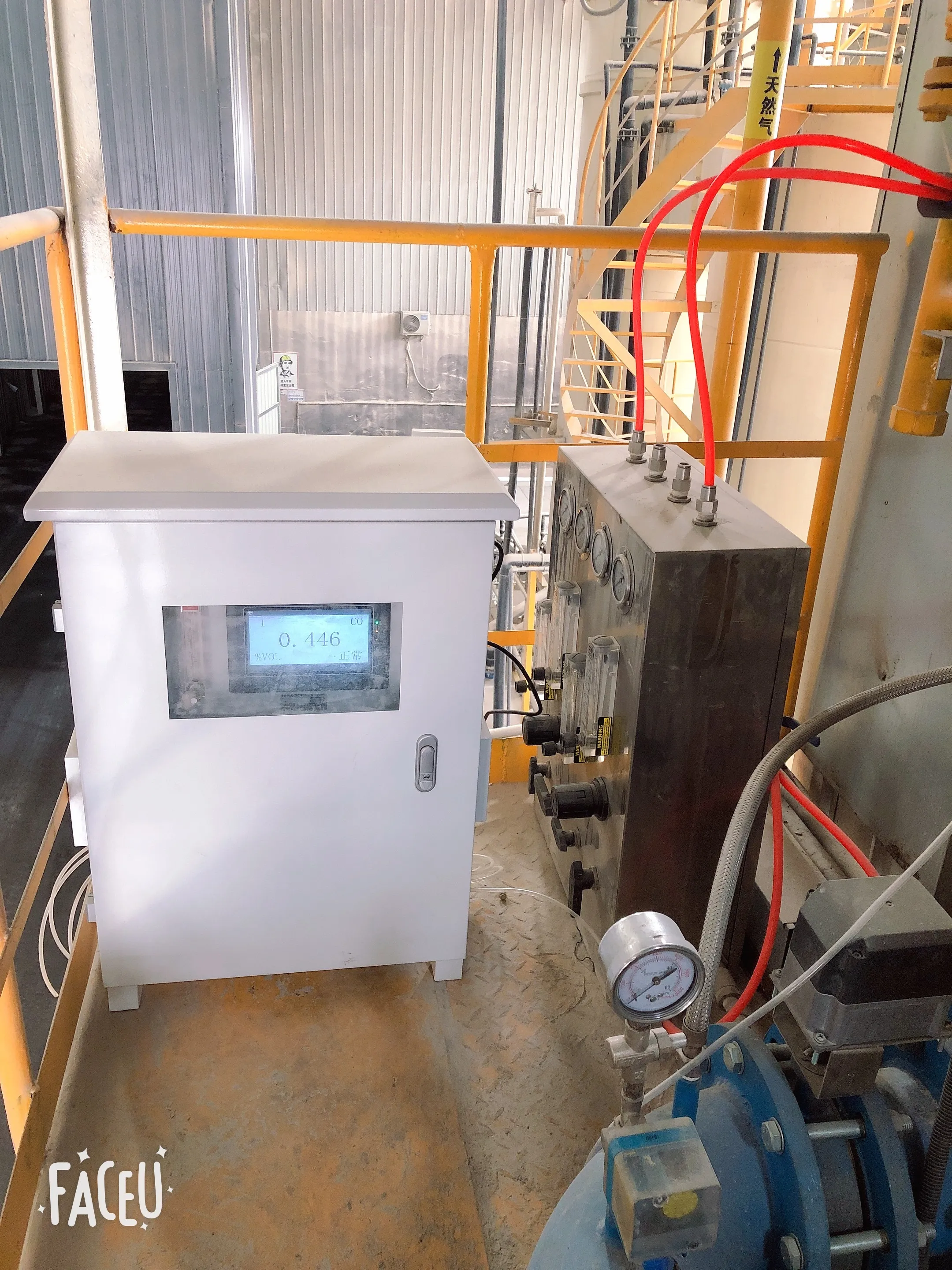

A chemical enterprise generates waste gas containing volatile organic compounds (VOCs) during production, which needs to be discharged through a chimney pipeline. In order to grasp the concentration of VOCs in the waste gas in real time and ensure that the emission meets environmental protection standards, the enterprise has installed an online gas pretreatment device.

The sampling probe of the device goes deep into the chimney pipeline to collect the waste gas. After the gas is subjected to dust removal, dehumidification and other treatments by the pretreatment system, it is transmitted to the monitoring instrument. The staff can intuitively see the VOCs concentration value through the instrument screen. For example, a certain monitoring showed that the concentration was 4.4 ppm, which was within the normal emission range. The application of this device enables the enterprise to realize the real-time monitoring of waste gas emission, helps it meet environmental protection requirements, and also provides reliable data support for the supervision of environmental protection departments.

|

|

|

Case Background: "Safety Blind Spots" and "Efficiency Bottlenecks" in Kiln Production

- In terms of safety, data lagged by several hours. In case of a sudden concentration increase, on-site personnel could hardly evacuate in time. There were multiple equipment failures triggered by excessive CO concentration, and even near-miss safety accidents.

- In terms of production, it was impossible to grasp the real-time relationship between concentration changes and combustion efficiency. Process adjustments could only be made based on experience, resulting in fuel waste and large fluctuations in product quality.

Breaking the Dilemma: Precision Attack with Customized Online Monitoring System

Step 1: Purification Journey of "Dirty Sample Gas" from Flue to Gas Path

Step 2: Real-time Sentinel in Hazardous Areas

Step 3: Data-Driven "Process Optimization"

Results: Two-Way Pursuit of Safety and Production

- Safety Dimension: From "post-event traceability" to "pre-event early warning", no safety accidents caused by abnormal CO concentration have occurred since the system was put into use, and the sense of security of on-site personnel has been significantly improved.

- Production Dimension: From "experience-based exploration" to "data-driven decision-making", the efficiency of process adjustment has increased by more than 30%, and both energy consumption costs and product defect rates have decreased.

- Management Dimension: The historical data reports generated by the system provide a quantitative basis for equipment operation and maintenance and process iteration, promoting the transformation of enterprise management to "intelligent and refined".

A chemical enterprise generates waste gas containing volatile organic compounds (VOCs) during production, which needs to be discharged through a chimney pipeline. In order to grasp the concentration of VOCs in the waste gas in real time and ensure that the emission meets environmental protection standards, the enterprise has installed an online gas pretreatment device.

The sampling probe of the device goes deep into the chimney pipeline to collect the waste gas. After the gas is subjected to dust removal, dehumidification and other treatments by the pretreatment system, it is transmitted to the monitoring instrument. The staff can intuitively see the VOCs concentration value through the instrument screen. For example, a certain monitoring showed that the concentration was 4.4 ppm, which was within the normal emission range. The application of this device enables the enterprise to realize the real-time monitoring of waste gas emission, helps it meet environmental protection requirements, and also provides reliable data support for the supervision of environmental protection departments.

|

|

|

Case Background: "Safety Blind Spots" and "Efficiency Bottlenecks" in Kiln Production

- In terms of safety, data lagged by several hours. In case of a sudden concentration increase, on-site personnel could hardly evacuate in time. There were multiple equipment failures triggered by excessive CO concentration, and even near-miss safety accidents.

- In terms of production, it was impossible to grasp the real-time relationship between concentration changes and combustion efficiency. Process adjustments could only be made based on experience, resulting in fuel waste and large fluctuations in product quality.

Breaking the Dilemma: Precision Attack with Customized Online Monitoring System

Step 1: Purification Journey of "Dirty Sample Gas" from Flue to Gas Path

Step 2: Real-time Sentinel in Hazardous Areas

Step 3: Data-Driven "Process Optimization"

Results: Two-Way Pursuit of Safety and Production

- Safety Dimension: From "post-event traceability" to "pre-event early warning", no safety accidents caused by abnormal CO concentration have occurred since the system was put into use, and the sense of security of on-site personnel has been significantly improved.

- Production Dimension: From "experience-based exploration" to "data-driven decision-making", the efficiency of process adjustment has increased by more than 30%, and both energy consumption costs and product defect rates have decreased.

- Management Dimension: The historical data reports generated by the system provide a quantitative basis for equipment operation and maintenance and process iteration, promoting the transformation of enterprise management to "intelligent and refined".